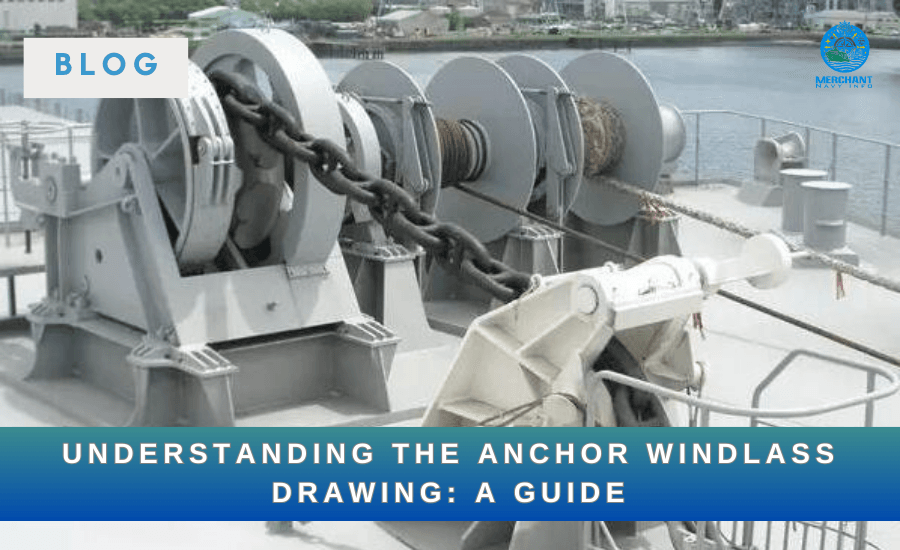

Components of an Anchor Windlass

When it comes to anchoring a ship, one of the most crucial pieces of equipment on board is the anchor windlass. This powerful mechanical device not only ensures that anchors can be easily deployed and retrieved but also plays a critical role in the overall safety and efficiency of maritime operations. In this detailed guide, we’ll explore an anchor windlass’s components, operation, and maintenance.

- Windlass Drum:

- Function: The drum is where the anchor chain or rope is wound. It provides the necessary mechanical advantage to lift and lower the anchor.

- Design: Typically designed to handle the immense load of the anchor and chain, ensuring smooth and controlled operation. Drums are often grooved to guide the chain evenly and prevent slipping or tangling.

- Gypsy (Wildcat):

- Function: The gypsy is specifically designed to grip the links of the anchor chain, preventing slipping during operation.

- Importance: It is crucial to pull the chain in or let it out accurately and efficiently. The gypsy’s teeth fit precisely into the chain links, ensuring a firm hold and smooth motion.

- Brake:

- Function: Used to control the speed of the anchor chain during deployment or retrieval, preventing it from running out too quickly.

- Types: These can be mechanical, hydraulic, or a combination, depending on the windlass design. The brake is essential for safe operations, providing the ability to halt the chain’s movement quickly if necessary.

- Motor:

- Types: Windlasses can be powered by electric, hydraulic, or manual systems, depending on the size and type of the vessel.

- Role: Provide the necessary force to operate the windlass and handle the heavy loads. Electric and hydraulic motors are common in modern windlasses, offering reliable and powerful performance with easy control.

- Control Lever:

- Function: Allows the operator to control the windlass, including options for heaving in, veering out, or stopping the chain.

- Location: Typically found on the deck or in the ship’s control room for easy access. Advanced systems may include remote control options, enhancing operational flexibility.

- Chain Pipe (Hawse Pipe):

- Function: Guides the anchor chain from the windlass to the chain locker below the deck.

- Design: Ensures smooth operation and prevents tangling or damage to the chain. The chain pipe must be robust and well-maintained to handle the harsh marine environment.

- Chain Locker:

- Function: Storage area for the anchor chain, usually located below the windlass.

- Importance: Keeps the chain organized and prevents it from getting entangled. A well-designed chain locker has proper drainage and ventilation to prevent corrosion and damage to the chain.

Orion’s Belt Stars & Their Importance

What Are Tugboats, Types, & Its Uses

Basic Operation of an Anchor Windlass

- Deploying the Anchor:

- Preparation: Release the brake to allow the chain to run out smoothly. Ensure the chain is free from obstructions and the anchor is clear to drop.

- Control: Use the control lever to let the chain out as the anchor is lowered into the water. Monitor the chain’s movement and adjust the speed as necessary.

- Brake Application: Apply the brake to control the descent speed and stop the chain when the desired length is out. This prevents the anchor from falling too quickly and ensures it sets correctly on the seabed.

- Retrieving the Anchor:

- Start Operation: Engage the motor and use the control lever to start heaving in the chain. Ensure the chain is winding evenly on the drum, and monitor for any kinks or snags.

- Gypsy Functionality: The gypsy grips the chain and pulls it onto the windlass drum. The secure grip ensures a steady and controlled retrieval process.

- Chain Storage: The chain pipe directs the chain into the chain locker below the deck. Ensure the chain is stored neatly to prevent tangling and ease future deployments.

- Completion: Once the anchor is aboard, securely apply the brake to ensure it remains in place. Inspect the anchor and chain for any damage or wear.

How Does an Anchor Windlass Work?

- Raising the Anchor:

- Activation: The power source activates the gearbox, which drives the wildcat drum.

- Operation: The wildcat drum rotates, winding the anchor chain onto itself.

- Result: As the chain winds onto the drum, the anchor is gradually pulled from the seabed.

- Lowering the Anchor:

- Brake Release: The brake is released, allowing the wildcat drum to rotate freely.

- Operation: The anchor chain unwinds from the drum, and the anchor descends into the water.

Types of Anchor Windlasses

Anchor windlasses come in various types, each suited to specific vessel sizes and operational requirements:

- Hydraulic Windlass:

- Power Source: Utilizes hydraulic power to operate.

- Control: Offers smooth and precise control over the anchor’s movement.

- Application: Commonly used on larger vessels due to its powerful and reliable performance.

- Electric Windlass:

- Power Source: Powered by electricity.

- Ease of Use: Offers easy operation and maintenance.

- Application: Commonly used on smaller vessels and pleasure boats due to its convenience and efficiency.

- Manual Windlass:

- Operation: Requires significant manual effort to operate.

- Application: Less common, but still used on smaller boats where simplicity and cost-effectiveness are priorities.

The Importance of Anchor Windlasses

Anchor windlasses play a crucial role in ensuring the safety and stability of vessels. By efficiently deploying and retrieving anchors, they help ships to:

- Maintain Position:

- Stability: Anchor windlasses enable ships to maintain their position in various weather conditions, preventing them from drifting or colliding with other vessels.

- Precision: Ensures precise anchoring positions, crucial for avoiding hazards and maintaining the ship’s course.

- Secure the Vessel:

- Reliability: Anchors provide a reliable means of securing a vessel to the seabed, especially in harbors or during storms.

- Safety: A properly anchored vessel is less likely to encounter mishaps, enhancing the safety of both the crew and the ship.

- Facilitate Safe Operations:

- Efficiency: By ensuring anchors’ safe and efficient handling, windlasses contribute to the overall safety of maritime operations.

- Ease of Use: Modern windlasses make the process of anchoring and weighing anchors easier and less labor-intensive, reducing the risk of injuries.

Safety and Maintenance

Regular maintenance and safety checks ensure the anchor windlass operates efficiently and reliably. Here are some key maintenance tips:

- Lubrication:

- Regularly lubricate moving parts to ensure smooth operation and prevent wear and tear. Use marine-grade lubricants suitable for the windlass components.

- Inspection:

- Inspect the anchor chain for wear, corrosion, or damage. Replace any worn or damaged links to prevent failures during operation.

- Check the gypsy for proper functioning and grip on the chain. Ensure the teeth are not worn, and the gypsy rotates smoothly.

- Motor Maintenance:

- Ensure the motor is in good working condition, with no signs of overheating or electrical issues. Regularly check electrical connections and hydraulic lines for leaks or damage.

- Brake Functionality:

- Regularly test the brake to ensure it can adequately control the descent and retrieval of the anchor chain. Adjust or replace brake components as needed to maintain optimal performance.

- Control Systems:

- Verify that the control levers and other systems are responsive and functioning correctly. Test all control options, including remote controls if equipped, to ensure they operate as expected.

Conclusion

An anchor windlass is an indispensable piece of equipment on any ship, facilitating the safe and efficient deployment and retrieval of the anchor. Understanding its components and operation and regular maintenance ensure that maritime operations remain smooth and secure. Whether you’re a seasoned mariner or just starting to learn about ship equipment, a well-maintained anchor windlass is crucial for successful anchoring.

Incorporating these practices into your routine will not only extend the life of your windlass but also enhance the safety and efficiency of your vessel’s anchoring procedures. Always follow the manufacturer’s guidelines and seek professional assistance for complex maintenance tasks.

The next time you see a large ship anchored in a harbor, take a moment to appreciate the unsung hero that keeps it securely in place – the mighty anchor windlass.