A line throwing appliance is a type of life-saving equipment fitted on every ship. It is used to throw a weighted rope, called a line, over long distances. They are discharged in a variety of ways and can be used for a variety of maritime applications. From transporting goods, connecting ships and providing supply lines to assisting in rescue operations, line throwing appliances are an essential part of every ship, whether sailing the oceans or domestic waters. This article looks at the history, development, types and specifications of line throwing appliances.

History And Origins Of The Line-Throwing Device

Line throwing appliance have been used in various forms for centuries. Originally, they were thrown by hand, but they had a short range and were not very accurate. Problems arose with wind-powered boats and ships, as they were dependent on wind speed, the wind direction, and also the accuracy of the operator. To compensate for this inefficiency, in 1791, John Bell developed the idea for a system that could be used to cast a line from a ship.

This system should be used in emergency situations during rescue operations. Although this is one of the earliest recorded the instances of a mechanical line throwing appliance, the idea did not catch on and was not widely implemented. During the 19th century, several inventions were implemented that allowed lines to be cast short distances from ships. These were primarily intended for salvage operations, and one or two were soon implemented on most ships.

The Manby mortar of 1808 was invented by Captain George William Manby, inventor of the portable fire extinguisher, and was the first in a series of commercial line-launching devices. A mortar design was used to throw ropes at shipwrecked or stranded sailors. It is believed to be the first mass-launched device, saving over 1,000 lives by the time its inventor died. However, it only worked short distances, could only be fired from shore, and was too heavy to be easily transported.

The Rocket Life-Saving Device

It was invented by Henry Trengraus as the rope launcher, which next became standard equipment on most ships. It had a longer range and was much lighter than the Manby mortar. The Trengraus design used a rocket fixed to a cradle instead of a mortar; in most cases, a nearby chair or other equipment could be used as a support mount. In addition, the rocket accelerated gradually on launch so that the rope did not snap immediately, a problem commonly associated with mortar systems.

The Trengraus design was popular with sailors because it could be used as a shipboard and was easy to transport. The next innovation in rope throwing was the Lyle gun, a short-barreled cannon made for throwing ropes. It was invented by Lt. David A. Lyle of the USLSS and was used primarily by the United States Life Saving Service (USLSS). The Lyle rifle was used until 1952 when it was replaced by the rocket-powered line.

The head attached to the line was usually made of cast iron and was powered by gunpowder. There was a significant problem with recoil, as a standard shot could throw the rifle back more than six feet. This design was primarily used for shipwreck salvage from land and allowed the cannon to be properly secured to prevent backfire.

Line throwing appliance Types, Functions, and Operation

Modern line throwing appliances are powered by rockets, pneumatic systems, or sling mechanisms. They fall into two main drive categories:

- pyrotechnic

- pneumatic.

Pyrotechnic Systems

They use ignition to ignite the line, while pneumatic systems use built-up pressure. Pyrotechnic systems are volatile and also can be extremely dangerous if accidentally ignited. In response to the growing concerns about the safety of fireworks systems, pneumatic launchers were invented and came into widespread use in the late 20th century. A rocket-based launcher is a type of ignition system that is often preferred because it meets SOLAS requirements and is readily available commercially. It involves the ignition of a main rocket attached to a line made of a strong material that can bend without breaking.

Another modern device is the shoulder-launched line launcher, similar to a shoulder-launched rocket propulsion system. This provides better stability and is usually light enough to be easily transported. The driving force of the ignition system gives it a very long range. Slingshot mechanisms also have a long-range and are considered very accurate. Most of them systems can be operated by one person and are portable.

The Pneumatic Line

Launcher is a very common launcher mechanism that has been in use since the late 20th century. Despite the prevalence of other technologies, this technology is still used today for ship-to-ship and ship-to-ship applications. This system uses Newton’s third law, which means that every action has an equal and opposite reaction. The built-up pressure in the launch module throws the line and weighted projectile forward. Because the driving force is air-generated, there is no risk of recoil or reverse shock. Range and direction are determined by the amount of pressure built up.

Lighter lines are made of Dacron or Spectra and are often used as carrier lines to pull heavier, more durable lines made of Polyspectra or Polypropylene. Pneumatic systems can also launch the vertical lines that can be used for vertical ascents. It is often used to board a ship from a small boat, for anti-piracy or tactical naval operations. These systems use a titanium grappling hook that can support the transport of heavy loads.

Line Casting Equipment

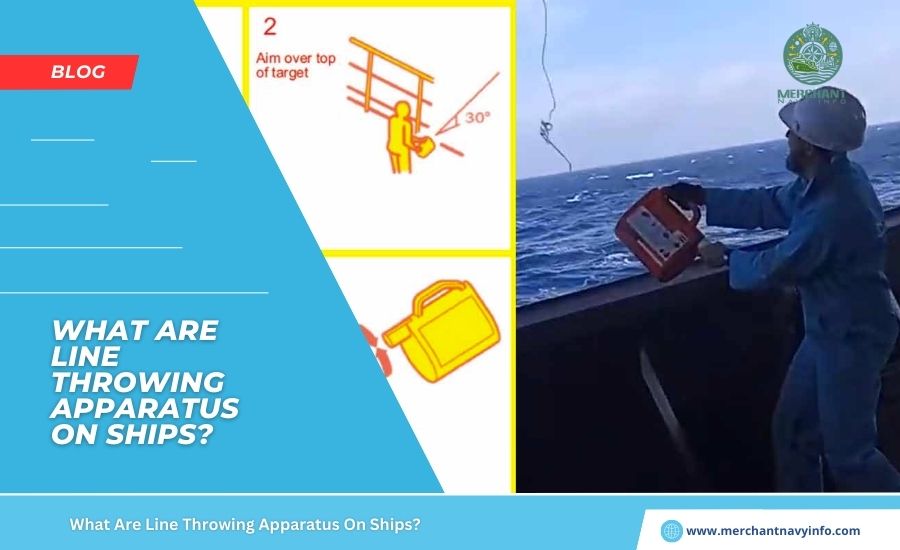

It is usually stored on the bridge as this is the main control centre of the ship. Special container units are provided to store the device on board. The unit consists of the rope attached to a head, which is coiled inside a storage cylinder. The cylinder assembly is spring-loaded and has a trigger for actuation. To operate the device, the unit is mounted on a bollard or similar stable structure. This is to stabilize one end of the device. Once you have reached the correct target, you need to trigger the device. Pressing the lever will send the line and head flying outwards. Preferably, the whole assembly should be held at a 45° angle to the ship’s deck to allow the projectile to travel the maximum possible range.

Additionally, driving the components into the wind direction can increase the range. Ropes are primarily used for ship logistics and rescue operations. For logistics support, the rope is thrown to another ship or to a floating supply box. For a supply box, the rope has a hook that allows it to hook onto the load and pull it safely to the ship. Another ship or supply vessel, the rope is thrown out, and the other vessel picks it up. Another rope is then thrown over to secure the connection. The box or package containing the goods is pulled on the connecting line. Finally, the line is released from the supply vessel and towed back to the ship.