What is the Hull of A Ship?

The hull is one of the most important parts of any vessel. Without it, a ship is nothing more than a hull that cannot float or sail. But what is a structure, what functions does it perform, and why is it so important? In this article, we will explain everything you need to know about the hull, including its design, materials, and how it affects the ship’s overall performance.

Structure Definition and Its Functions

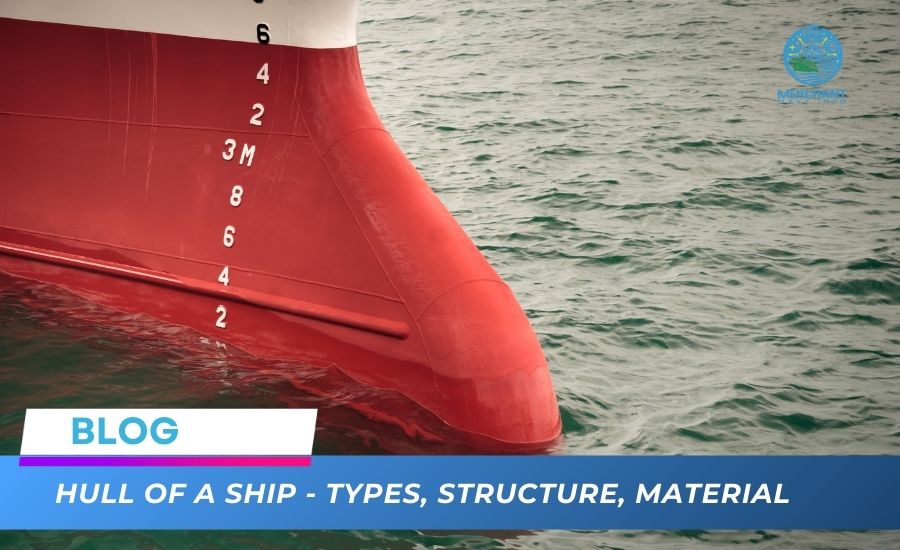

The hull is the external structure that makes up the main part of the ship, allowing it to float and sail in the water. The surface is in direct contact with the water and provides the stability needed to keep the ship afloat even in adverse conditions. The hull acts as the “skin” of the ship, protecting the interior of the ship from flooding and supporting the weight of the hull and cargo on board.

The design of the hull must be strong enough to withstand the impact of waves and other natural elements, but it must also be light and aerodynamic so that the ship can move efficiently through the water. Good hull design is key to increasing the speed, maneuverability, and fuel efficiency of the ship.

Structure Types by Shape

The hull’s shape varies depending on the type of ship and its intended purpose. Below we explain the most common types:

1. Displacement structure

The offset hull is the most traditional hull and is often found on cruise ships and large ships. This type of hull is designed to displace a large amount of water when moving forward, providing stable and efficient sailing at low speeds. Displacement hull boats are ideal for long-distance sailing because their shape allows them to move smoothly through the water with relatively low fuel consumption.

2. Planing structure

Planing hulls are common on sports boats and powerboats, such as some Crownline models. Unlike displacement hulls, planing hulls are designed to “lift” out of the water when a certain speed is reached, reducing friction and allowing the boat to reach higher speeds. These hulls are ideal for those who seek speed and agility on the water, providing an exciting and dynamic experience.

3. Semi-displacement structure

This type of structure combines the characteristics of displacement structure and planning structure. This is common in boats that require speed and stability. Semi-displacement hulls allow the boat to move efficiently at low speeds, but can also be partially lifted out of the water to reach higher speeds. This design is ideal for boats that need versatility in different sailing conditions.

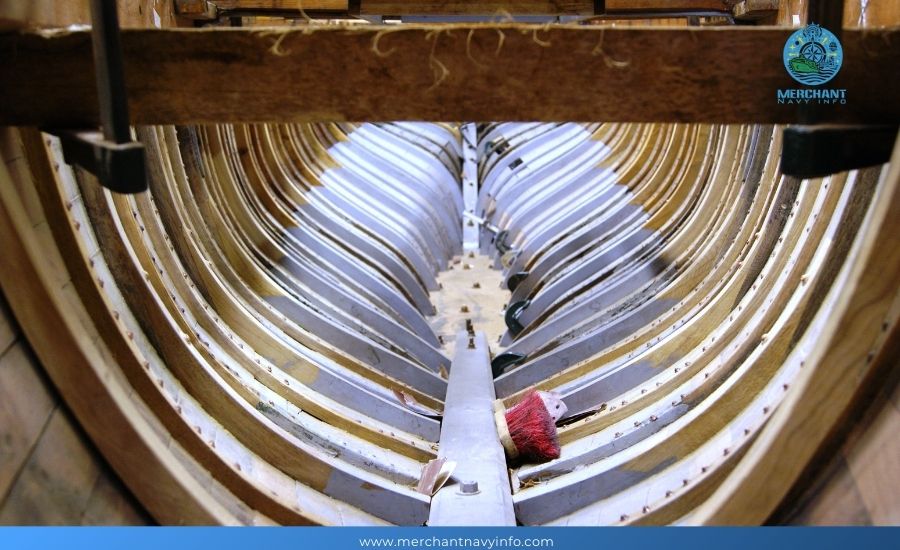

Materials Used To Build The Structure

The materials used to build the structure are crucial to its performance, durability, and maintenance. Below we explain the most commonly used materials in hull construction:

1. Fiberglass

Fiberglass is one of the most popular building structural materials due to its durability, corrosion resistance, and low maintenance. It is lightweight yet strong, and offers excellent maneuverability and speed. For example, Crownline Marine uses fiberglass in its hulls, giving it a perfect combination of performance and longevity.

2. Aluminum

Aluminum is another commonly used material, especially in smaller boats and boats designed for speed. It is lightweight, corrosion-resistant, and easier to repair than other materials. Also, aluminum frames are known for their durability and ability to withstand impacts without sustaining significant damage.

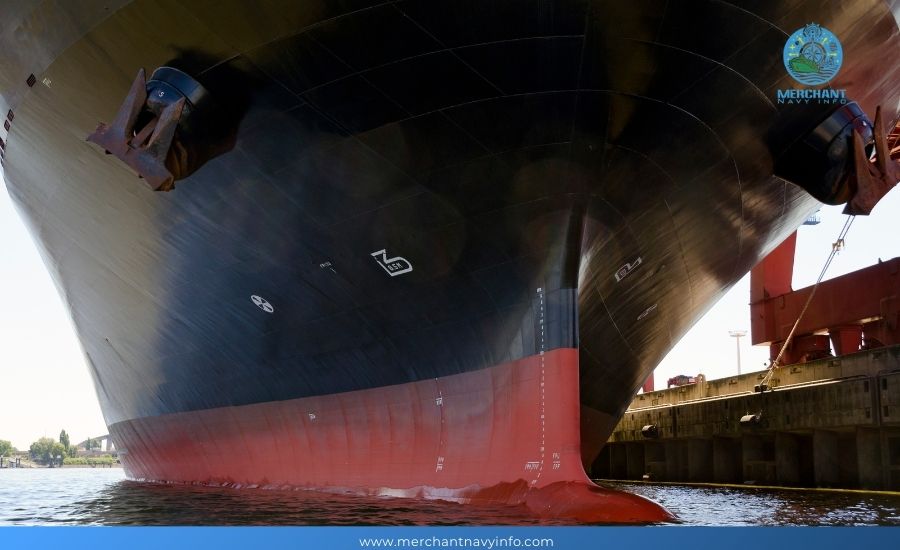

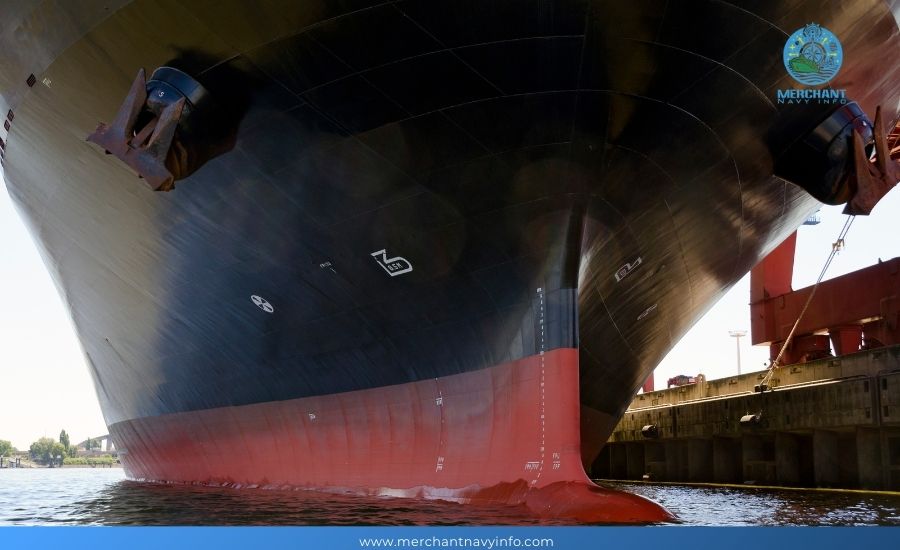

3. Steel

Steel is primarily used in larger boats, such as yachts and commercial vessels. Although it is heavier than fiberglass and aluminum, it has superior strength, making it an ideal choice for boats that navigate difficult conditions. The steel is impact-resistant and can withstand corrosion and damage from long-term exposure to salt water.

Hull Maintenance: What You Should Remember?

Keeping your boat hull in good condition is essential to ensure the safety and performance of your boat. Here are some key aspects of structural maintenance:

1. Regular cleaning

Cleaning the hull is essential to prevent the buildup of algae, seaweed, and other marine organisms that increase friction and reduce the efficiency of the vessel. It is recommended to clean the hull regularly, especially when used in salt water, where deposits will occur more quickly.

2. Damage inspection

It is essential to regularly inspect the undercarriage for cracks, dents, or other damage. Any damage, no matter how small, will compromise the structural integrity of the hull and affect the performance of the vessel. If a problem is found, it must be resolved as soon as possible to avoid major problems.

3. Antifouling

Antifouling is a special coating applied to the hull of the ship that prevents marine organisms from attaching to the surface. This coating must be applied regularly to keep the hull in perfect condition and ensure that the boat moves efficiently in the water.

How Hull Design Affects the Sailing Experience

Hull design not only affects the performance of a vessel, but also the boating experience. A good hull design can make a boat faster, more stable, and easier to maneuver. Additionally, a well-designed hull can improve onboard comfort by reducing wave action, which is especially important for leisure boats.

Naval engineers spend a lot of time and effort designing hulls that are not only efficient but also provide an enjoyable cruising experience. From choosing the hull shape to the materials used, every design decision directly impacts how the boat performs on the water and how it feels to sailors.