Wind Meets Recycling In The Freight Industry

Finally, the freight industry is getting serious about reducing global greenhouse gas emissions. In a world where everything old is new again, wind power is emerging as a key solution. Advocates of battery electric power are also pushing for a seat at the table in decarbonization talks, and a new study suggests they may be right—but only if long-distance travel is exempted altogether.

Wind power for the 21st-century freight industry

When someone compares wind power and cargo ships these days, they’re not usually referring to large sheets of fabric stretched out in the breeze. Shipping stakeholders provide wind power in rigid devices that differ from traditional sails (see more background on rigid sails here).

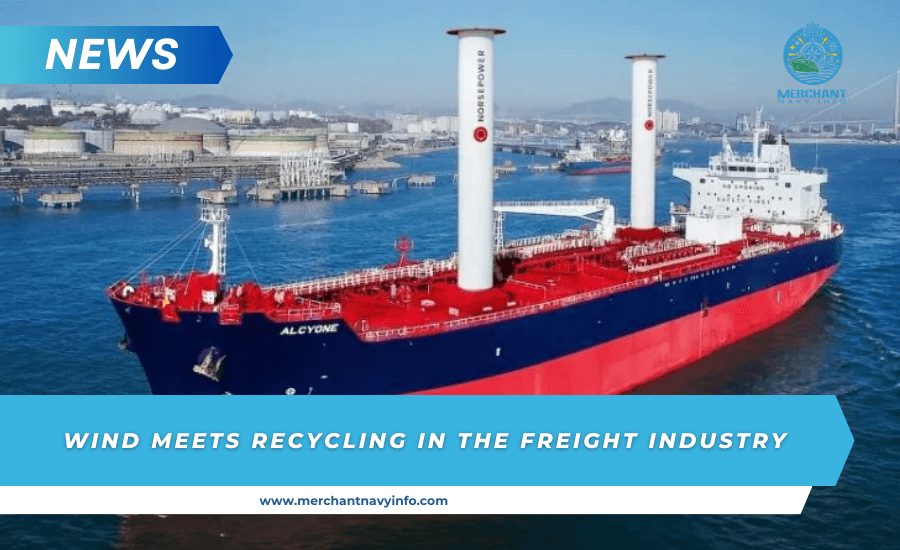

One technology that has caught Cleantechnica’s eye is a long, rotating cylinder that looks like an oversized chimney. It was developed by the Finnish company Norsepower and marketed as the Rotor Sail.

The resemblance to a chimney is only superficial. Rotor sails take advantage of the Mangus effect, a phenomenon that occurs when a rotating object moves through the air.

“When the wind hits the rotor sail, the airflow speeds up on one side of the rotor sail and slows down on the other side of the rotor sail,” explains Norris Power. “The change in airflow speed causes a pressure difference, which generates lift. Perpendicular to the direction of the wind flow.”

Tiltable wind power device made from recycled plastic

Norris Power has launched a business model that aims to fully exploit its unique approach to harvesting wind energy for cargo ships, starting with fuel savings of up to 28% or more, depending on the situation. Norris Power has also promoted the Rotor Sail as a tiltable device that can be in a horizontal position, allowing ships to pass under low bridges. Within the framework of sustainable development, the device can be installed on existing ships as well as on new vessels.

Norris Power has also recently received approval to market the Rotor Sail as an explosion-proof wind energy device, allowing it to be placed in hazardous areas on commercial vessels. The certificate was issued by international classification society DNV.

“As the first-ever approval for the use of a wind-assisted propulsion system (WAPS) in hazardous areas on board ships, DNV’s certification of the NPRS™ EX version marks a new milestone in the maritime sector,” the company explains.

As attention turns to lifecycle emissions and biodiversity conservation, Norse Power has also worked with the Nordic Green Bank NEFCO on a biodiversity pilot project.

“During the programme, NEFCO helped Norris Power map its impact on biodiversity, viable processes and circular economy concepts for the wind industry,” Nefco explains. The circular economy part includes using recycled plastics to make rotor sails.

Norris Power CEO Thomas Riske told Nordic Green Bank Nefco last year that “a typical sail could hold 300,000 bottles of recycled PET”, which would capture PET for at least 25 years, which is equivalent to the expected lifetime of a wind energy device.

More recycling for future sails

The PET recycling timeline of more than 25 years is an interesting contrast to other circular economy deployments for recycled plastics. The plastics industry is very focused on recycling old plastic bottles into new ones. This can help avoid extracting crude oil to meet the needs of the petrochemical industry, but it continues a repetitive cycle of energy consumption, depleting transportation fuel as well as resources at recycling facilities.

If you have any thoughts on this, please leave us a note in the comments. Meanwhile, Norris Power has added another type of recycling to its wind energy menu. In addition to spreading recycled material into the rotor sail, the whole thing can be hoisted up and transferred to another ship.

“The rotor sail can be removed from one ship and installed on another,” Jukka Koskowski, chief customer operations officer at Norspor, told Seatrade Maritime News in September last year, when the company was conducting its first “recycling upgrade.” “It’s easier.”

“It’s an advantage when an owner decides to sell or retire a vessel with a Norspor rotor sail, because the rotor sail unit can be refurbished and installed on the next ship to reduce fuel consumption and emissions for many years,” Koskowski explained.

“We believe that when the number of rotor sails installed on the market increases and the demand for Norspor’s standard rotor sails increases, such a second-hand market will emerge,” he added.

Wind power is good, battery wind power is better.

To maximize fuel savings on rotor sails and other wind equipment, shipping companies can also implement advanced route planning techniques that allow them to take advantage of favorable wind conditions. This increases the possibility of abandoning liquid fuels entirely and relying on a combination of battery power and wind power.

This may be a difficult goal to achieve, at least for cargo ships. “While better battery technology in recent years has enabled electric vehicles to have greater range, ships are much heavier than cars and can travel long distances between ports,” said the U.S. Department of Energy’s Lawrence Berkeley National Laboratory. “The temperatures and long distances have led some to believe that electrification of freight transport is impossible.”

However, recent advances in battery technology have made the impossible possible. “Lower battery costs, combined with increasing battery energy density, a clean grid, improved ship operations, and evaluating the second life of batteries, create a unique opportunity to electrify transportation,” explained Won Young Park, an energy policy researcher at Berkeley Lab.”

Park is the lead author of a new Berkeley Lab study that shows that passenger ships are ready for electrification if long-distance voyages are excluded. The results can be extrapolated to apply to cargo ships as well.

Park and his colleagues found that reducing long-distance voyages by just 1% could make ship electrification more feasible, allowing the use of batteries that are two-thirds smaller than those required for long-distance voyages. For passenger ships, they found, the size could be reduced by 85%, as the research team sees tugboat power as low-hanging fruit for charging electrification.

Some shipping stakeholders are also focusing their attention on other areas. Close attention is being paid to specialized shipping services that deploy wind power on small cargo ships, which can visit a wide range of seaports and benefit from competitive warehouse-to-warehouse schedules.