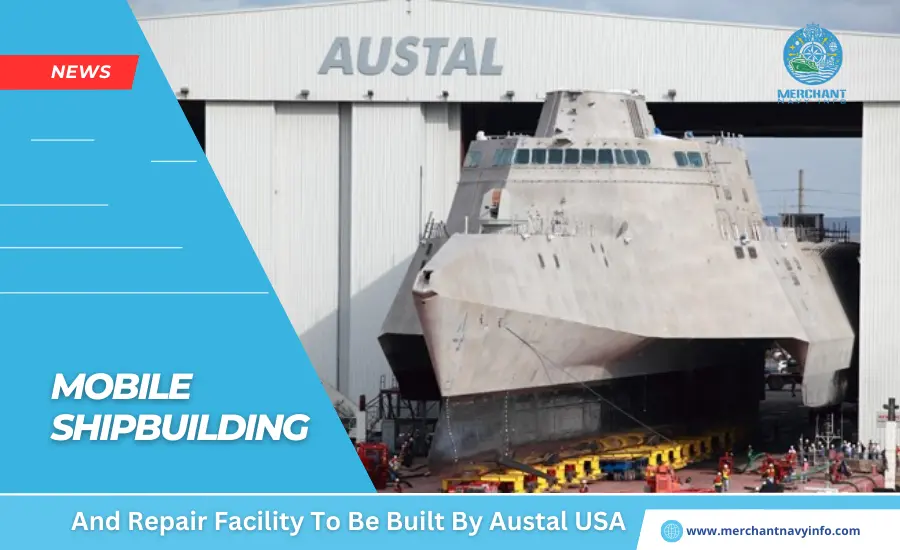

Austal USA, a U.S. naval shipbuilding and repair company. Will invest in a multi-million dollar shipyard with ship lifting. And transfer systems adjacent to its current facility in Mobile, Alabama. Austal’s infrastructure expansion will take place south of the current shipyard in Mobile. And will include a new assembly building, waterfront improvements, and a new Pearlson-designed ship lift and transfer system. Construction on the new facility is expected to begin this summer.

Austal USA worked with Pearlson & Pearlson, the program manager and owner representative. Kiewit Infrastructure South Co., Design and Construction Director. and Pearlson Shiplift Corp. will execute the project. The Vessel Lifting System has an articulated lifting platform 137.16 m x 38.1 m capable of lifting and launching vessels over 18,000 tons in length. The Pearlson Shiplift is capable of supporting the U.S. Navy’s new Constellation class frigates, TAGOS-25 class ocean surveillance ships, Independence-class littoral combat ships, and Heritage class maritime patrol cutters.

Meanwhile, Florida-based Pearlson Shiplift is also currently building a new large ship lift, transfer system, and shore repair berth for the BAE Systems Jacksonville Ship Repair Shop in north Florida, scheduled to open in 2025. Designed and delivered. The shipyard’s ship lift measures 150 m x 33.5 m and can lift a U.S. Navy Flight III missile destroyer or a commercial ship with a displacement of approximately 25,000 tons. The new repair facility in Jacksonville will increase BAE Systems’ dry dock capacity by 300% to repair and maintain U.S. Navy surface ships based at Naval Base Mayport and commercial vessels calling at the Port of Jacksonville. The new facility is also the largest ship lifting, transfer system and shore repair yard in the Americas.