What is an Oil Water Separator? How Does an Oil Water Separator Work?

Industrial manufacturing industries, such as steel production, mining, food processing, tank truck washing, power generation, heavy equipment washing, etc., use water in their production processes and often produce wastewater that contains oil from various sources. The oil must be separated and removed before the water can be reused or discharged to a municipal water treatment plant.

More than ever, industrial facilities must find effective and efficient oil-water separation solutions in their daily operations. In addition to protecting the environment, the proper design of an oil-water separator can improve overall operations while reducing costs, avoiding fines, and even generating potential revenue. If you have oil water in your facility, learn what an industrial oil water separator is, how it works, and why it can be a useful and profitable addition to your operations.

What is an Oil Water Separator?

The American Petroleum Institute (API) Oil/Water Separator was developed by the American Petroleum Institute and Rex Chain Belt Company and was first installed in 1933 at Atlantic Refining Company in Philadelphia, Pennsylvania. In short, an API Oil/Water Separator is a device designed to separate oil and suspended solids from industrial wastewater sources, such as refineries, oil processing facilities, petrochemical and chemical plants, natural gas processing plants, and more.

Since the advent of the API Standard Oil/Water Separator, most refineries worldwide and many companies in various industries (from railroads to steel mills) have installed some industrial oil/water separator to aid in wastewater treatment for industrial facilities or organizations that need to separate oil from wastewater, industrial oil/water separation systems are essential to operational success.

How Do Oil/Water Separators Work?

Used in some of the most challenging applications around the world, an oil/water separator is a flow device designed to separate oil from industrial wastewater, process water, and stormwater.

The Science Behind Industrial Oil/Water Separation Systems

Under certain conditions, oil separates from water due to the difference in specific gravity between the two liquids. The speed at which oil separates from the lighter liquid is explained by Stoke’s Law, a formula that helps determine how fast a drop of oil will rise or sink based on the following factors:

- The density and size of the oil drop.

- The distance the body must travel.

- The volume of the collection tank.

Oil/water separators are designed with these factors in mind, helping to create the ideal conditions required for oil and water separation. There are two main oil/water separators: gravity separators, API oil/water separators, and melt separators.

Types of Oil/Water Separators

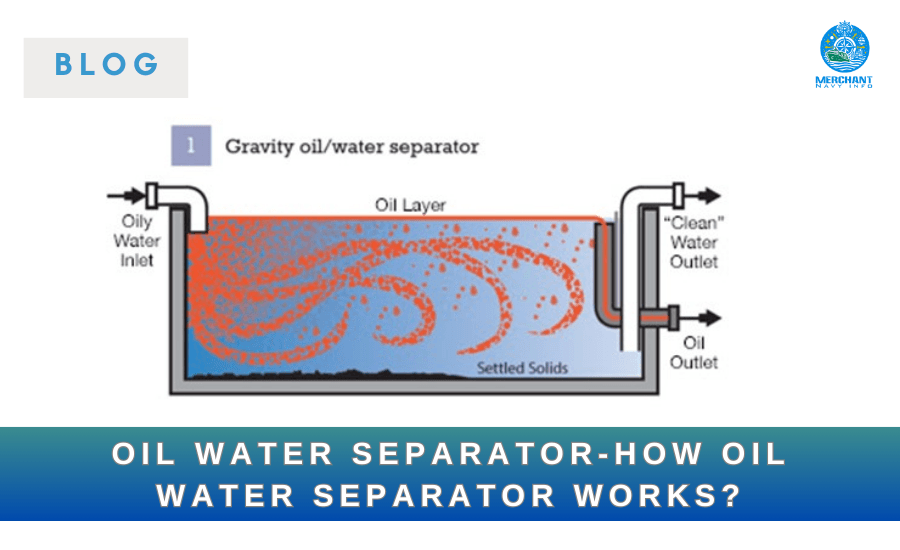

1. Gravity Oil/Water Separators or API Separators

This type of industrial oil/water separator is based on the difference between the specific gravity of water and the specific gravity of oil and works as follows:

Oily water enters the separator inlet. When the water encounters an obstruction, the turbulence of the water is reduced, and most of the solids settle to the bottom of the separator.

As the wastewater flows through the oil/water separator, the oil droplets float to the water’s surface but are prevented from leaving the separator by a second baffle; any remaining solids settle out.

2. Combination Oil/Water Separators

In a combination separator, the overall flow of oil and water through the separator is similar to a gravity separation device. However, the oil and water flow through an oleophilic medium in a combination separator. This additional step allows the oil droplets to adhere to each other on the surface of the medium. By merging or sticking together, oil droplets become more buoyant, rising to the surface faster and further facilitating separation.

What are the benefits of an oil/water separator?

With a properly designed oil/water separator, oily process water or wastewater facilities can effectively separate the oil from the water before reusing or discharging the clean water to a sewer or back to the environment. With the right separator design for your specific conditions and application, you can achieve the following benefits:

Better oil removal – When oily water has enough time and space to separate into two distinct layers effectively, the oil can float on the water’s surface. The de-oiler can remove the oil more easily and effectively.

Better wastewater treatment – By separating and removing oil from wastewater before chemical treatment or filtration, the treatment process will be more effective, and the filtration equipment will last longer and perform better.

Environmental Compliance – Oil water separators produce cleaner wastewater that meets local and federal regulatory requirements.

Less Maintenance – When the proper oil-water separator is selected and meets the application challenges, efficient oil separation and removal can be achieved, which means less maintenance is required to keep the separator operational, and post-processing equipment will operate more efficiently.

Revenue Generating Potential: In some cases, the recovered oil can be sold as a valuable product.