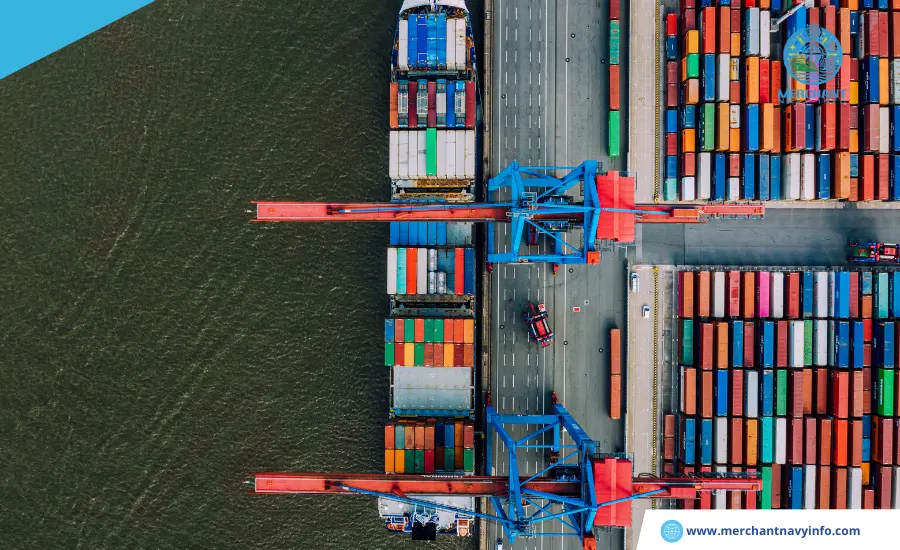

The cargo industry is worth an trillions of dollars. A wide variety of goods are transported around the world, from shipping fresh produce to aircraft parts. The global shipping industry relies on hundreds of vessels that ply the world’s oceans. They range from small fishing boats and speedboats to giant monsters such as heavy lift vessels (HLVs). In addition to container ships Supramax commonly used for shipping, there is another class of vessel known as bulk carriers.

These are ships that transport large amounts of bulk cargo without dividing it into smaller pieces like container ships. One such type of cargo ship is the Supramax class. Although they are considered relatively small among bulk carriers, they are still in heavy use around the world today. In this article, we delve deeper into the world of bulk carriers, particularly the Supramax class. We analyze the design, construction and safety aspects of these ships.

Bulk Carriers

Bulk cargo refers to goods and items that are transported loose and unpackaged. To understand what this means, consider the class of container ship. Container ships measure the loads in the units they transport. These can be boxes, pallets, cartons, etc. A key specification for goods transported in containers is that the goods must be maintained in a particular condition during transport. For example, boxes of soda cans cannot be handled forcefully because they would lose pressure rapidly during transport and eventually cause gas leaks; therefore, they are stored on pallets inside the container. Similarly, fresh produce and vegetables cannot simply be stored loosely inside a container because they would be subject to pressure points and scrapes during transport; they are stored in special boxes with protective coatings on the edges. Thus, container ships transport goods that need to be kept stable.

How Do You Transport An Incalculable Commodity, Say, Rice?

Rice can’t be measured by the number of individual grains. Instead, a weight system is used to calculate the amount transported. If you decided to transport rice in containers, loading and unloading would be a nightmare: the grain would get stuck in every nook and cranny and could shift during travel. It would be dangerous to open the container doors at the destination.

Instead of wasting plastic to package the rice into manageable units, it is easier to use a class of ships known as bulk carriers, which can accommodate large amounts of bulk goods. They are widely used to transport materials such as bulk grain, ore, and cement. The goods are stored in hatches below the deck. The operation is carried out using a crane system on the upper deck. Bulk carriers are divided into a number of size classes depending on their size and the route they travel. These include Aframax, Chinamax, Panamax, QMax (short for Qatar Max size) and Suezmax, named after the areas they are permitted to pass through due to dimensional restrictions. Depending on their nominal size, they are classified as Handymax, Supramax, etc.

Supramax Cargo Ships

The terms Supramax and Handymax are often used closely together but with important differences. The Handymax class includes ships with tonnages between 35,000 and 50,000 DWT, while the Supramax class is between 50,000 and 60,000 DWT. The term “capacity” refers to the total weight of cargo the ship can carry and does not include the weight of the ship or machinery. Instead, it includes cargo, fuel, ballast water, etc. Supramax ships are popular due to their relatively small size. They are suitable for berthing in ports around the world and are between 150 and 200 meters long. These vessels are one of the most common in the size class of vessels over 10,000 DWT. Their size allows them to pass through most canals and locks that other vessels cannot access.

For example

the Panama Canal and the Suez Canal have very strict to restrictions on the size of vessels that can pass through them. This has actually led to the creation of classes of vessels known as New Panamax and Suezmax. Supramax ships can navigate these straits and canals with ease. Interestingly, even Handymax ships are being converted to transport goods up to 55,000 deadweight tons. This is because the demand for Supramax ships remains high. Though there is a demand for such ships, they take a long time to build. These ships have multiple holds, so they can transport different types of cargo. For example, it is common to fill three or four holds with ore and the remaining holds with grain.

Depending on the route and logistical requirements, some holds may be unloaded at ports along the way. These empty holds are then filled with other goods that need to be unloaded at the final destination. This versatility of Supramax ships makes them advantageous for shipping around the world. In fact, such ships are in such high demand that most Handymax ships are being modified to meet Supramax specifications. In fact, nearly 80% of the world’s Supramax fleet is made up of modified Handymax carriers. During the economic boom of 2008, Japanese and Korean shipyards ramped up production of Handymax ships. At the time, the cost of building such a ship was nearly $40 million. After various economic collapses over the following decades, prices have dropped slightly. Today, a Supramax or Handymax ship costs between $25 million and $30 million.

Design and Layout of a Supramax Ship

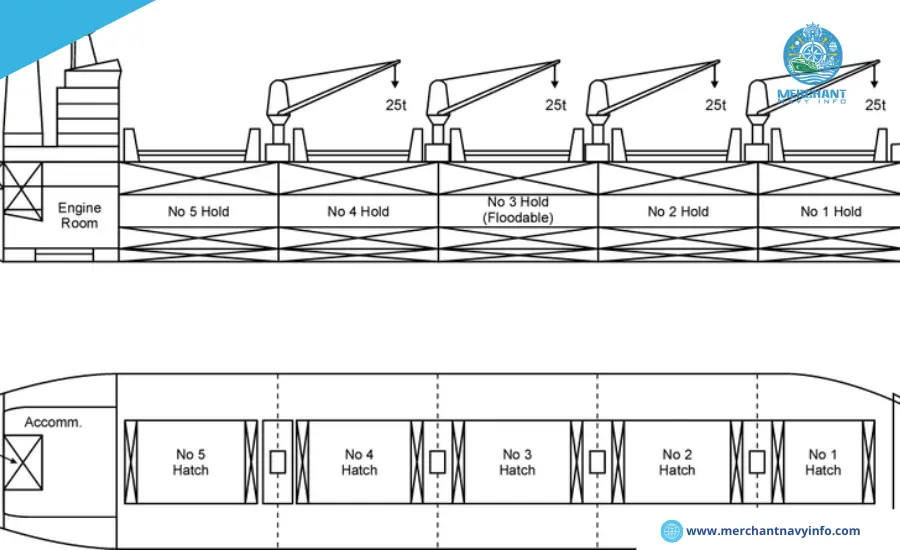

Starting with the upper deck, the ship usually has a superstructure at the stern. This structure houses the crew quarters, machinery, equipment, and bridge. The conventional superstructure of a Supramax vessel is 40 to 50 feet high. The remaining area of the upper deck is equipped with hatch covers and deck cranes. Conventional vessels typically have five watertight hatches. The hatch covers are operated using a hydraulic system that runs along the edge of the upper deck. To improve stability along the hatch openings, taller frame members are often added for support. There are usually four cranes on the upper deck. They assist in loading and unloading certain types of goods. This is very useful when a Supramax ship is berthed in a port that is not well equipped with crane facilities. In such cases, it reduces the turnaround time of the ship.

Lifting

The average lifting capacity of the cranes on Supramax ships is almost 30 tonnes. The cranes used are often double-jointed cranes. In terms of dimensions, Supramax ships are around 150-200 meters long and almost 30 meters wide. The total depth of the hull is 18-20 meters. In most cases, there is a limit to the maximum allowable draft of these vessels. For larger ships, the draft can be around 13 meters, while for smaller vessels, the draft is limited to 10-12 meters.

The current specifications for a modern Supramax ship are 199 meters long, 32 meters wide, and 12.Two meters draft, and 18.8 meters deep. The engine area is mainly found in the engine room under the body. The engine and propeller shaft are housed here and rest on a special platform designed to absorb shock and vibration The most commonly used engines are two-stroke marine diesel engines working in conjunction with fixed propellers. Modern versions of small craft use two four-stroke engines capable of driving adjustable pitch propellers.

Operation of Supramax Ships

The Operation of Supramax ships may vary depending on the main route and type of cargo. Crews on such vessels can range from, say, 10 to almost 30 people. Larger variants often require more personnel for maintenance and repair work, while smaller vessels can get by with a crew of just 10. Officer numbers usually remain under five, including the chief engineer, captain and deck officer. The routes that most Supramax vessels travel depend on the economics of supply and demand. For example, a ship carrying ore on the outbound journey may be carrying grain on the return journey. These ships would be able to pass through most locks and canals and would not be restricted by the main shipping lanes. To go from the Atlantic to the Pacific, they could also use the Panama Canal rather than going around South America.

Similarly, Supramax ships would take the Suez Canal route through Europe and Asia instead of going around the Cape of Good Hope. Another important factor when choosing a shipping route is journey time. Bulk carriers are known to spend a lot of time loading and unloading. While container ships take 12 hours, Supramax ships can stay up to 60 hours in port. With the installation of deck cranes, the journey time is somewhat shorter, but it is still considered one of the longest in the shipping industry.