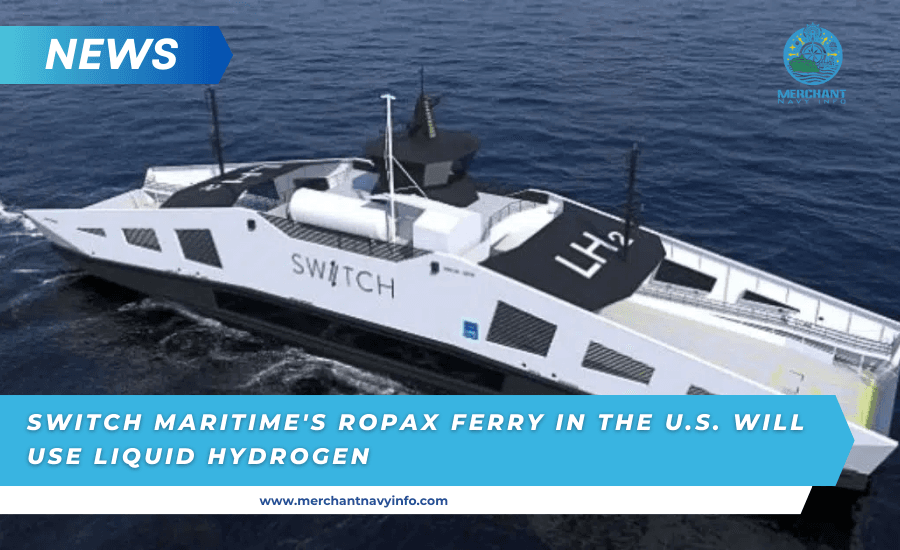

SWITCH Maritime is building the first RoPax ferry in the U.S. powered by liquid hydrogen

The maritime industry is working to reduce carbon emissions by having companies build more sustainable ships.

The latest development is SWITCH Maritime, which works with LMG Marin and LH2 Shipping to build the first RoPax ferry in the U.S. powered by liquid hydrogen. The ferry will emit only H20 vapor and no carbon.

SWITCH Maritime’s first hydrogen-powered ship is the Sea Change. It is a catamaran with room for 75 passengers.

It has a 600-kW electric motor propulsion system powered by a 360-kW fuel cell and stores 246 kg of hydrogen. The Sea Change began operating as part of the San Francisco Bay Ferry system in July.

SWITCH founder and CEO Pace Ralli said the company is ready to take the lead in providing carbon-neutral liquefied hydrogen for high-power and heavy vessels.

The company is looking to build a vessel using an LMG Marin design. Designed to accommodate 80 cars and 300 passengers, the RoPax vehicle ferry is DNV-classified and successfully operated by Norled.

The MF Hydra ferry uses liquid hydrogen to travel six nautical miles on round trip. It has a four-ton tank on its upper deck for storing liquid hydrogen and receives fuel from trucks via a refueling system. The ferry has been refueled about 50 times since its operations in 2023.

The ferry being built in the US will have a speed of 14 knots and will only need to be refueled once a week without recharging in port.

Although the design will be modified to meet US Coast Guard requirements, SWITCH says the massive steel hull makes it more spacious and has a weight advantage over aluminum hull ferries.

The liquid hydrogen evaporates from the tank and is used in proton exchange membrane fuel cells to generate engine electricity.

SWITCH also builds a San Francisco Bay Ferry Service catamaran using a gaseous hydrogen storage system and fuel cells. For larger ships carrying 300 or more passengers, the company plans to move from gaseous, liquid hydrogen storage to cryogenic storage.

Compressed hydrogen is feasible for small and medium-sized vessels, but as size and power requirements increase, the company said cryogenic liquefied hydrogen is the preferred storage solution. Refrigerated LH2 supports fast refueling speeds at larger volumes.