The trim and stability of a ship measures its uprightness, i.e., how the ship stays on the water level. In a broader sense, this uprightness can be seen from two perspectives. And the trim and stability of a ship can be described in two ways:

i) Longitudinal stability

ii) Transverse stability.

Transverse Stability

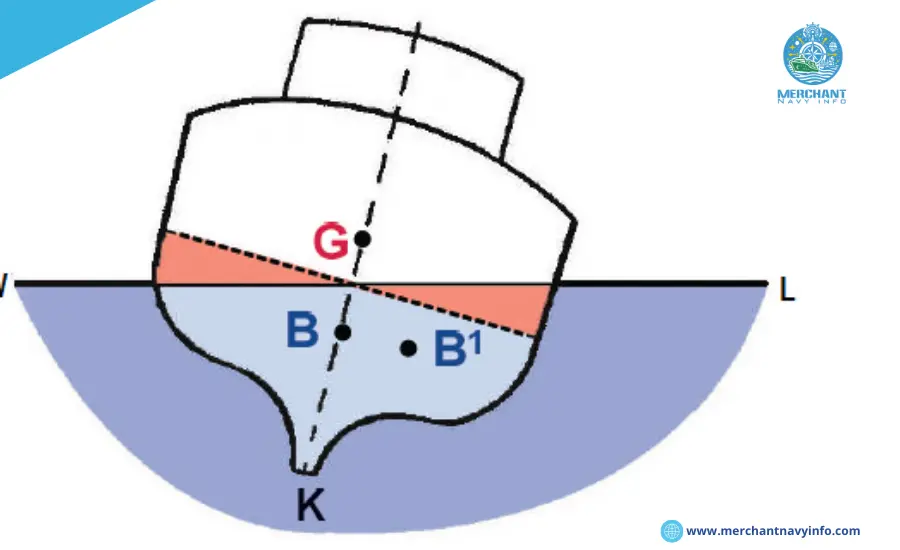

Transverse trim and stability refer to the tendency of the ship to remain upright. When viewed longitudinally or from the front or rear. So, let us look at a cross-section or a front view of the ship. Now, if the ship is listing to port or starboard about its longitudinal axis or, in technical terms. The center line of the ship, then we say that the ship has lost its uprightness. When a ship lists to starboard. The draft is greater on the starboard side than on the port side, and vice versa when the ship lists to port.

We also looked at various aspects of lateral trim and stability. Including the disturbance forces that cause this loss of uprightness, heel and list (remember the difference?). And the myriad of technical terms related to this subject, such as the centre of buoyancy. Learned about the centre of gravity, the metacentre, height, righting arm and more. We also learned about the list experiment and how to obtain trim and stability. Let’s take a quick look at another aspect of ship trim and stability.

Ship Trim And A Brief On Longitudinal Stability

A brief discussion of ship trim and longitudinal stability is a measure of the “uprightness” of a ship. When viewed from its side or side. This means looking at the length of the ship from both sides. Uprightness here is defined as the state of the ship remaining level. Or horizontal to the waterline throughout its entire length. Suppose this state is disturbed, and the bow or stern tips forward or backward, changing the straight waterline. This is called the ship’s Trim.

In other words, if the draft or water level is different or changes throughout the entire length of the ship. The ship is said to be trimmed. When the draft or water level at the bow or front of the ship is higher than at the stern or aft. The ship is said to be in bow or fore trim. Conversely, when the draft at the stern or aft is higher than at the bow, it is called aft or aft Trim. The cause of such a difference in the longitudinal draft of a ship. May be various factors more or less similar to those affecting the transverse stability. External factors, such as weather and sea conditions, or internal factors, such as loads and weight transfers.

Measuring Trim:

Measuring trim is important to designers and ship operators alike. Simply put, Trim is the mathematical difference between the forward and aft drafts measured at the ends of the ship. Consider a ship with a draft TF measured at its forward end and a draft TA measured at its aft end. The difference in the ship’s net Trim is +/- (TF – TA). The trim angle is also important when considering Trim. A ship is immersed differently at the front and rear, causing the waterline to change predictably along its length.

Assuming the waterline is a straight line for basic calculation purposes. And ignoring effects such as waves and ripples. The old and new waterlines will intersect at some point along the length of the ship. The equal and opposite angles contained at the point of intersection are called the trim angles. According to simple laws of geometry, this is directly proportional. To the degree of Trim the ship is undergoing at that point.

A Brief Introduction To The Physics Of Trim And Longitudinal Stability

Since Trim is caused by external or internal forces and their associated moments, from a physics point of view, these forces and moments have to act somewhere to achieve the desired trimming effect. As explained in the last section, these basically act around a horizontal axis that passes through the point where the original and new waterlines intersect. This point is called the centre of floating, or F. This point is also the geometric centre of gravity of the ship at the waterline at a particular time. Suppose a weight is added at a point that is on the same vertical line as the centre of the floating. In this case, for physical reasons, any type of force acting on the centre of mass will not cause a change in the resulting moment, which will remain effectively zero, so there will be no change in net Trim;

The distance KM from the keel to the metacentre is the sum of the distance KB between the keel and the centre of buoyancy and the metacentric radius BM, which will be the vertical distance between the centre of buoyancy and the metacentre M, or the sum of the distance KG between the keel and the centre of gravity and the metacentric height GM (the distance between G and M). All values are similar to those discussed in terms of transverse stability. However, as already mentioned, certain dimensions, such as KM, GM, and BM, are relevant from the point of view of longitudinal stability. For practical reasons, they are marked with the subscript L.

Detailed Aspects

We will not go into these detailed aspects, and the associated calculations and derivations, as they are beyond the scope of this article, which is primarily aimed at understanding trim stability and longitudinal stability. A very important quantity in our discussion, but one that we need to discuss, is the moment that triggers the Trim or MCT. As we have already seen, a trim is always associated with a triggering moment. Therefore, a specific moment must be assigned to a specific trim t. In the simplest case, when a transfer of a weight w occurs from one point to another over a certain distance h, the moment is simply the product w x h.

The situation is similar when an internal load changes, for example when a weight is added at a point. In this case, the moment can be considered as the product of the added weight w’ and the distance, say l, from the specified point to the centre of floating F. However, in the case of external causes causing Trim, the scenario is different. There are classifications and other empirical relationships to determine the resulting forces and moments, such as in the case of lateral stability. However, for convenience, trim moments have been standardized to determine the ease or minimum effort required to achieve the trim. Now the question arises: what is standardized to? The answer is “standardized to provide a one-size-fits-all trim.”

Now, Note The Last Term:

This means that, given the vessel’s configuration, the minimum torque to achieve this standard Trim can be determined from physical relationships. This is given as W x GML / L, where W is the displacement, GML is the longitudinal metacentric height, and L is the length of the ship. We will not go into detail on the derivation of this relationship and its impact on calculations. The term “unit trim” can be ambiguous. The above relationship basically gives the moment that will cause 1 meter of Trim.

If you want to get the moment that will cause just 1cm of Trim, just divide the above quantity by 100. This was further standardized as MCT1cm. Similarly, the above relationship can be appropriately converted to read in other units, such as feet or inches, although centimetres and meters are the two most common units today. MCT also helps in estimating the draft at which a vessel is likely to float under certain loading conditions.

Useful Trim

Unlike heeling and listing, Trim is not necessarily bad. In fact, most modern ocean-going vessels have some degree of Trim to increase efficiency, unlike in the past when they simply maintained a constant fixed design draft. From a hydrodynamic point of view, a certain amount of Trim at the stern is very important for many vessels to allow a good immersion of the propeller and, as a consequence, its efficiency.