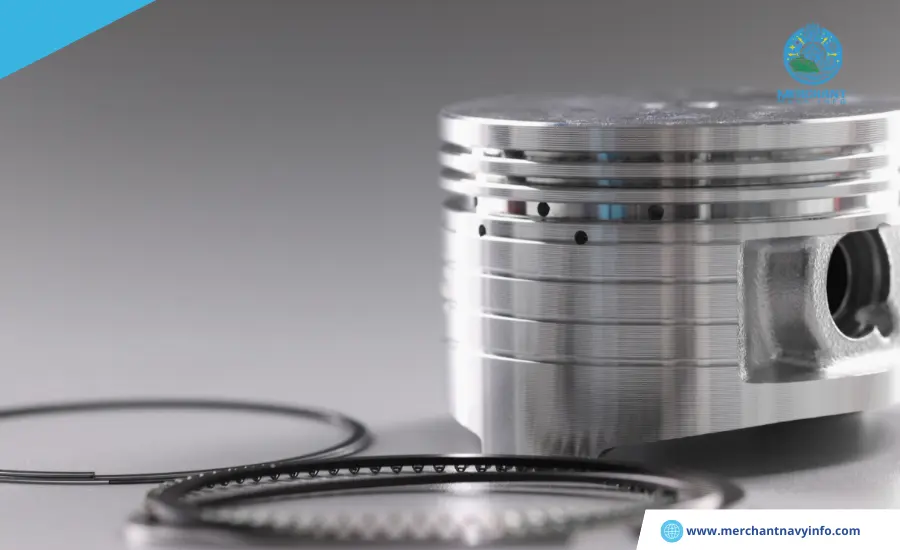

Piston rings are manufactured and classified according to their function and usage. The main purpose of a piston ring is to seal the chamber (where the piston travels). This is the combustion chamber in a two-stroke or four-stroke engine. Marine engines have a three or more types of rings around the circumference of the piston. Piston rings are an integral part of the piston, and their number. And function vary depending on the type and performance of the engine. Large two-stroke engines use compression piston rings to seal the combustion chamber.

A wiper ring is installed underneath and wipes debris. From the liner and distributes oil on the surface of the liner. However, in small marine engines, other types of piston rings are used for specific purposes. For example, oil scraper rings are used in four-stroke engines. Because they are short, and the crankcase oil has direct access to the cylinder liner and piston. This article explains the different types of piston rings used in marine engines.

Types of Piston Rings and Functions

Compression Ring or Pressure Ring Compression rings seal the top of the piston. And prevent gas leakage from the combustion side. Compression rings are found in the first groove of the piston. However, this may vary depending on the engine design. The main function of these rings is to seal the combustion gases. And transfer heat from the piston to the piston wall. The oil is controlled by scraping off the layer of oil left by the oil ring. Thereby properly lubricating the upper compression ring. In addition, it also assists in sealing and heat transfer for the upper compression ring.

Wiper Ring

The wiper ring, also known as the Napier ring or backup compression ring, is installed under the compression ring. Its main function is to remove excess oil from the cylinder bore and act as a backup ring to prevent gases from escaping further down the upper compression ring. Most wiper rings have a downward-facing conical surface that provides a wiping effect as the piston moves toward the crankshaft. If the wiper ring is installed incorrectly and the cone angle is closest to the compression ring, excessive oil consumption will occur. This is caused by the wiper ring is wiping excess oil towards the combustion chamber.

Oil Control/Scraper Ring

The Oil Control Ring regulates the amount of lubricating oil flowing up and down the cylinder wall. These rings also help distribute the oil evenly around the liner. Oil is sprayed onto the cylinder walls. These rings are also known as wiper rings because they remove the oil from to the cylinder walls and return it to the crankcase. These rings prevent oil from leaking between the ring surface and the cylinder. Oil rings have a hole or slot cut in the radial center of the ring to allow excess oil to return to the container. Oil scraper rings can be one-piece or two-piece. To increase the contact pressure between the ring and the liner surface, the rings can have chamfered edges on the outside of the land or towards the combustion chamber, improving the removal of oil from the bore and, therefore, reducing oil consumption.

Piston Ring Materials

Cast iron is one of the most commonly used materials for manufacturing piston rings. It contains lamellar graphite, which itself acts as a lubricant and supports the sliding motion between the ring and the liner. Piston rings come with different alloys and coatings depending on the type of ring as the rings have different functions from one another. The most commonly used alloys for cast iron are chromium, molybdenum, vanadium, titanium, nickel, and copper. To ensure maximum service life, the piston ring material is to kept harder than the cylinder liner.

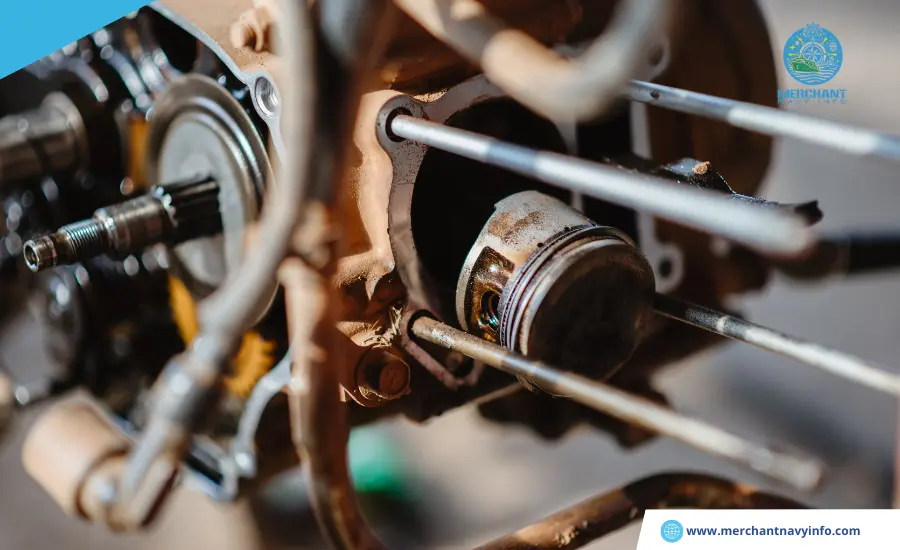

Main engine piston

The combustion chamber of a marine two-stroke engine is a large space that generates enormous heat and stress. The upper ring of the piston is in direct contact with the combustion chamber and, therefore, requires better protection and coating to withstand the thermal stresses and ensure a good seal. Many new designs have been introduced specifically for large two-stroke marine engines.

Some Of The Important Designs Introduced Are:

Man Engine

The upper piston ring is of the controlled pressure relief type, with several inclined flat grooves (hard chrome plated) in the face which allow some gas pressure to pass through to the second piston ring etc. This reduces the strain on the upper ring. The ends of the ring are connected in an S-shape. Recently, a new design has also been introduced, which is a modified version of the CPR ring known as the CPR Port on Plain Ring (CPR POP). It was observed that the groove in the CPR ring on the barrel side was wearing faster than normal so the location of the groove has been changed and it is now at the bottom of the ring.

Second Or Intermediate Ring:

The other rings have an angled cut on the ring end. All piston rings are aluminum coated on the outer surface to facilitate break-in.

Wärtsila Engines

In Wärtsila two-stroke engines, the piston ring grooves on the piston is surface are hardened to provide excellent wear resistance. The upper piston ring (also called the Gas Tight (GT) ring at Wartsila) has an asymmetric barrel shape with overlapping ends to prevent gas leakage. It is coated with Chrome Ceramic (CC) and has a run-in finish (RC). The number of piston rings varies depending on the engine size. For example, the RTflex 35 has a very short shaft and is equipped with three piston rings, while an RTA engine may be equipped with five piston rings.

3 Four-Stroke Engines

The piston ring requirements for four-stroke engines are different because The piston-liner assembly is open to the oil pan. Therefore, an additional oil scraper ring is required in a four-stroke piston ring package. It usually consists of 2 to 5 rings, depending on the engine type and specifications. There are usually 2 to 4 compression rings to seal the gases from the combustion of chamber and 1 to 3 oil control rings to prevent excess oil from entering the combustion chamber. Compressor rings are usually barrel-shaped with tapered faces for an efficient gas seal. The oil scraper ring profile consists of two webs and a coil spring inserted to support the ring preload.

How Do Piston Rings Work?

As explained, there are an different types of rings at different levels in the piston, performing different tasks. The grooves at the top of the piston consist of compression rings, whose main function is to seal any kind of leakage in the combustion chamber during the combustion process. When the mixture is ignited, the piston head is pressurized by the combustion gases, forcing the piston towards the crankshaft. The pressurized gases flow through the gap between the cylinder wall and the piston into the piston ring grooves. During the combustion process, the force of the high-pressure gases presses the piston rings against the cylinder liner wall, helping to form an effective seal.

This pressure pushing against the piston rings is proportional to the pressure of the combustion gases. The next set of rings in the piston, below the compression rings, and above the oil rings, are called the wiper rings. They have a conical surface structure and serve to seal the combustion chamber further. As the name suggests, they help to remove excess oil and contaminants from the cylinder walls. If the combustion gases are able to pass through the compression rings, these gases will be blocked by the wiper rings in good condition. The final set of rings is the oil rings located in the bottom groove of the piston closest to the crankcase.

Why Do Piston Rings Fail?

The combustion chamber exerts a lot of pressure on the piston rings. If the combustion pressure of the gases generated in the chamber is higher than normal, it can affect the performance of the rings. This can be caused by fuel explosions and ringing from leaky injectors or a mixture of fuel and dirty air. Contaminated heating oil or the wrong type of cylinder oil can also affect the performance of the rings.

As the rings wear, their ability to seal out the combustion gases becomes evident. Common causes of piston ring wear are poor fuel or cylinder oil quality, poor combustion process, incorrect fuel timing, worn cylinder liners, etc. The most common sign of ring wear is gases entering the crankcase or area under the piston (also known as blow-by). Carbon and sludge buildup can make the rings sticky, and wear can cause the rings to break or crack.

What To Look For When Inspecting Piston Rings

Inspecting piston rings is an important task to determine if they are functioning properly. The piston rings are then cleaned or replaced (if damaged or worn). On a two-stroke engine, the top ring opening is usually higher than the top ring groove on a four-stroke engine.

During Routine Inspection

During routine inspection of the washroom, a screwdriver is used to press the piston rings. This is done to check the spring action or an tension of the rings. This also helps determine if the rings are broken, which will cause them to lose their spring action. The rings are checked for play in the grooves as they can become clogged due to carbon deposits and eventually break, causing serious damage to the liner. The play between the rings and the grooves is also checked, and the wear is calculated. The rings are checked for scuffs and damage, and their overall condition is assessed.

During A General Overhaul

During a general overhaul, the piston rings are completely replaced with new ones. However, if the rings are to be discarded, the following procedure must be followed:

- If the piston rings are found to be stuck in the grooves.

- When the axial height of the ring is reduced and the ring-groove clearance is large.

- When the chrome layer is chipped or damaged.