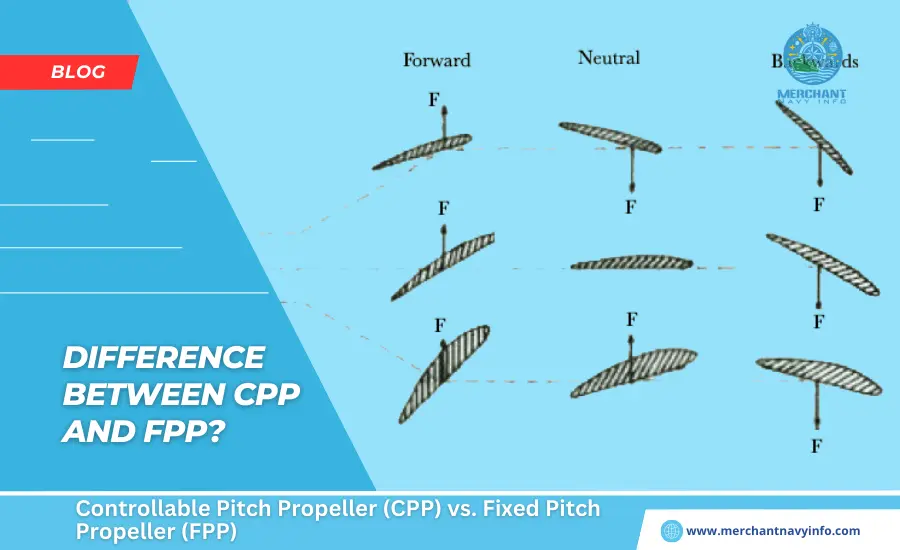

Most propellers used on marine vessels are fixed-pitch propellers (FPP). What does the term propeller mean? Let’s understand this from a beginner’s perspective. If you look at a controllable pitch propeller, you will also notice that the propeller blades rotate along the length of the propeller hub. This rotation of the blades causes the propeller to move forward with each revolution. It is almost similar to what you would find on a screw. The angle of the thread is actually called the lead angle. The higher the pitch angle, the greater the distance the screw covers in one revolution, i.e., the greater the pitch. Similarly, a propeller works on the screw principle, hence the term screw propeller.

So What Is A Fixed Pitch Propeller Or FPP?

Propellers are designed so that if you cut the propeller radially at any radius from the center, the cut surface of the propeller blades will have a constant pitch (its strength depends on the twist along the length of the hub). Now, if you finally rotate this cut section in the water, the axial distance it travels in one revolution is the slope of that section. If you change the radius at which you cut the section, the twist of the blades from root to tip will also change. From this, we can see that each section of the propeller has a specific pitch. The pitch is different at the propeller root and at the propeller tip. Hence, there is a change in slope from root to tip.

If the pitch of each section is different, what will The Pitch of the propeller be?

The answer is that the resulting pitch is the average of all the pitches of each section of the propeller. Note that while the pitch varies with blade cross-section (or with increasing distance from the propeller center), the net average or net pitch of the propeller remains constant. Such a propeller is a fixed propeller. Now, going back to the concept of a screw, what if we could somehow change the overall angle of inclination of the threads along the screw? If we could do this, we would actually change the lead angle, which would change the pitch of the screw.

This is exactly why controllable pitch propellers were developed by industry. We will look at applications in more detail later. But before that, it is important to know the basic function of a controllable pitch propeller (also called a variable pitch propeller). The twist of the root of the blade (hereafter called pitch) always occurs with respect to an angle it makes with the propeller hub.

What If We Could Change The Angle Of The Root’s Orientation?

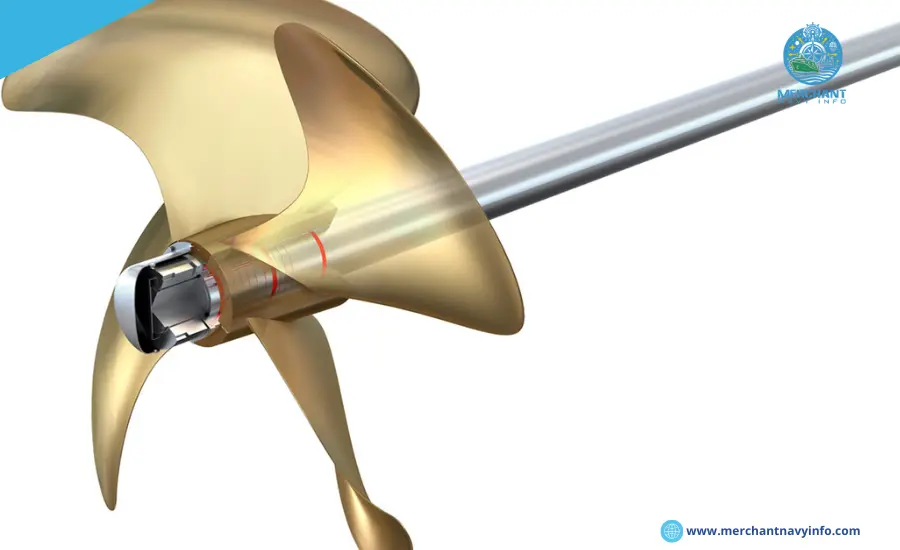

All the other blade sections already have the previous pitch angle set, so they get a new pitch angle. This means that by changing the orientation of the hub root, the pitch of the entire propeller can be controlled. This is done using hydraulic cylinders. Once the desired direction or pitch of the propeller is achieved, the blades are locked in this position. Therefore, the blades are not an integral part of the propeller hub (or cast together with it). They are mounted on a spindle whose axis is perpendicular to the shaft axis.

What are the 10 Parts of a Ship?

Advantages and Disadvantages of CPP and FPP

The following points explain the application and its relationship to the advantages and disadvantages of CPP and FPP systems:

A controllable pitch propeller can move a ship forward and also backward without changing the direction of the motor’s RPM. How? Propellers work on the principle of lift generated by each airfoil section of the rotor blade. What if we could change the direction of the rotor blade so that the direction of the vital force is opposite to the direction in which the ship moves forward? This is exactly what is achieved by changing the angle of the attack of the rotor blades.

Non-reversible engines can be used to propel a ship both forward and backward. Thus, the weight of the engine and propulsion machinery is significantly reduced compared to that required for a fixed-pitch propulsion system. Since the pitch of the propeller determines the thrust generated by the propeller, any change in the pitch angle can cause a change in the ship’s speed. Hence, controllable pitch propellers help in changing the ship’s speed without changing the main engine’s speed or RPM.

But Why Focus On This Advantage?

What if the engine speed needs to be reduced to reduce the ship’s speed? Many ships are equipped with shaft-driven diesel generator systems. Thus, the speed of the main motor shaft controls the amount of electricity generated on board. In this case, reducing speed with a fixed propeller requires a reduction in shaft speed, which results in less power being generated. For the reasons above, the ship’s speed can be controlled directly from the command bridge. With fixed propellers, the ship’s engineers have to be intimidated to change the ship’s speed. So, CPP technology is used to achieve faster response times to changes in speed. Efficiency in reverse gear is lower with a fixed pitch propeller than with a controllable pitch propeller in reverse gear.

However, there are many disadvantages to using a controllable pitch propeller over a fixed pitch propeller. It is important to know these too. The pitch control mechanism built into the hub is very complex and requires proper inspection at regular intervals. The installation process is also more complicated compared to fixed propeller systems. Controllable pitch propellers are very costly to acquire. These costs increase rapidly as the propeller diameter increases. With the pitch control mechanism built into the hub, the length and diameter of the hub are also larger compared to fixed propeller systems. Finally, it is important to know the possible applications of controllable pitch propellers. They are used on vessels that need to operate at variable speeds, even if they have a constant power requirement. Such vessels include tugs, trawlers, ferries, icebreakers, and small warships equipped with gas turbines.