Invasive aquatic species in ships’ ballast water is one of the biggest problems facing the shipping industry. These aquatic species pose a major threat to marine ecosystems, leading to an alarming increase in biological invasions. Based on the IMO’s “International Convention for the Management. And also Treatment of Ships’ Ballast Water and also Sediments”, the implementation of Ballast Water Treatment System And also ballast water treatment systems on board ships has become important.

To ensure that ships comply with the ballast water management rules and also regulations set out by IMO. Several shipping companies have started installing ballast water treatment systems on board their ships. There are numerous technologies available in the market for ship ballast water treatment. However, constraints such as availability of space, implementation costs and also environmental considerations play an important role in the use of a particular type of ballast water treatment system.

Many Factors

That are taken into consideration when selecting a ballast water treatment system for a ship. The most important factors taken into consideration are:

- Effectiveness against microorganisms in the ballast water

- Environmental considerations

- Crew safety

- Cost-effectiveness

- Ease of installation and also operation

- Space on board the ship

Ballast Water Treatment

The main ballast water treatment technologies available on the market are:

- Filtration systems (physical)

- Chemical disinfection (oxidizing and also non-oxidizing biocides)

- Ultraviolet light treatment

- Oxygen depletion treatment

- Heating (thermal treatment)

- Acoustic (cavitation treatment)

- Electric pulse/pulsed plasma systems

- Magnetic field treatment

A typical shipboard ballast water treatment system uses two or also more technologies together to ensure that is the treated ballast water is of IMO quality.

Physical Separation/Filtration Systems

Ballast water treatment Physical separation or filtration systems are used to separate marine organisms and suspended solids from the ballast water using settling or surface filtration systems. The suspended/filtered solids and wastewater (backwash water) from the filtration process are discharged to the area where ballast water is taken or further treated before being discharged back to the ship.

The following devices are primarily used for filtration of ballast water:

Screens/Discs:

Screens (fixed or movable) or discs are an used to effectively remove suspended solids from ballast water by automatic backwashing. Screens are very environmentally friendly as they do not require the use of toxic chemicals in the ballast water. Screen filtration is effective in removing larger-sized suspended solid particles but is less practical for removing smaller particles and organisms. screens are very effective in removing the majority of suspended solid particles and microorganisms from ballast water but have been found to be insufficient on their own to treat ballast water in accordance with IMO standards.

Hydrocyclones:

Hydrocyclones are an effective device for separating suspended solids from ballast water. High-speed centrifugal force spins the water to separate solids. Hydrocyclones have no moving parts, making them easy to install, operate and maintain on board ships. They have been found to be ineffective at removing small microorganisms from ballast water, as their operation is highly dependent on the mass and density of the particles.

Coagulation:

Because most physical filtration methods are unable to remove smaller solid particles, coagulation methods are used prior to the filtration process to bind the smaller particles together and increase their size. Increasing particle size increases the efficiency of the filter process described above. This process, where smaller particles clump together into small flakes, is called flocculation. The flakes settle faster and are easier to remove.Some ballast water treatment systems that employ flocculation and coagulation use additional powders (sand, magnetite, etc.) or coarse filters to create the flocs. This operation requires additional tanks to treat the ballast water, also thus requiring additional space on board.

Media Filters:

Physical ballast water treatment systems with an media filters can also be used to filter smaller particles. Compressible media filters (rubber granules) have been found to be more suitable for use on board ships due to their compact size and low density compared to traditional granular filter systems.

Magnetic Field Treatment

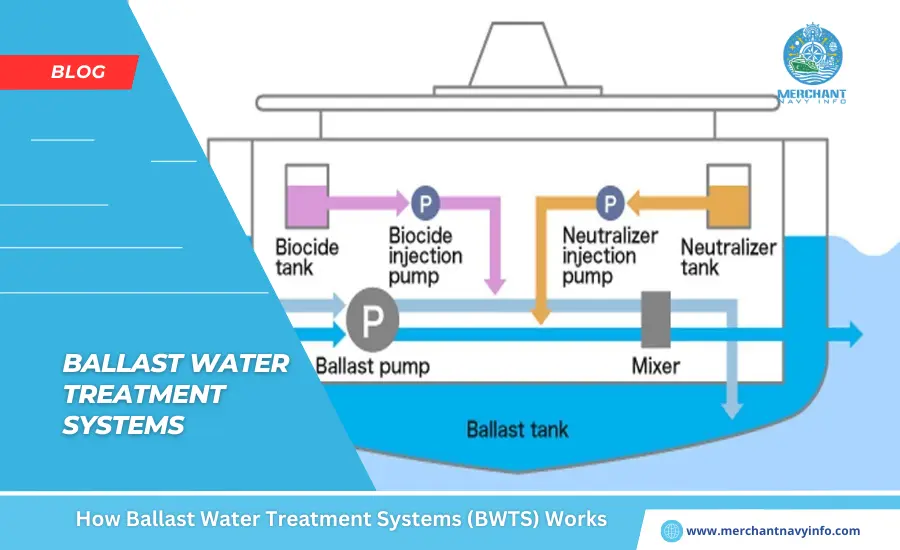

Magnetic field treatment utilizing coagulation technology. It is mixed with a flocculant and added to the ballast water. This forms magnetic flakes containing the marine organisms. Magnetic disks are used to separate these magnetic flakes from the water Chemical Disinfectants (Oxidizing and Non-Oxidizing Biocides) Ballast Water Treatment Biocides (Oxidizing and Non-Oxidizing) are disinfectants that have been tested for their potential to remove invasive organisms from ballast water.

Biocides remove or inactivate marine organisms in ballast water. However, it should be noted that biocides used for ballast water disinfection must be effective against marine organisms and easily degradable or removable to prevent toxicity in the effluent. Biocides are mainly classified into two types based on their function:

- Oxidizing

- Non-Oxidizing

Oxidizing Biocides:

Oxidizing biocides are common disinfectants such as chlorine, bromine and also iodine used to inactivate microorganisms in ballast water. This type of disinfectant works by destroying the organic structures of microorganisms, such as cell membranes and also nucleic acids.

Non-Oxidizing Biocides:

Non-Oxidizing Biocides are an type of disinfectant whose use destroys the reproductive, neurological or also metabolic functions of organisms. More information on biocides can be found at here. Oxidizing Biocides Processes in which oxidizing biocides are used on ships include:

- Chlorination – Chlorine is diluted with water to destroy microorganisms.

- Ozonation – Ozone gas is introduced into the ballast water using an ozone generator.

The ozone gas breaks down and reacts with other chemicals to kill organisms in the water. Other oxidizing biocides such as peracetic acid, chlorine dioxide, and also hydrogen peroxide are also used to kill organisms in the ballast water.

Non-Oxidizing Biocides

There are several non-oxidizing biocides on the market, but few are used in ballast water treatment systems, such as menadione/vitamin K, as they tend to produce toxic by-products. There is a lot of research being done in this area to make non-oxidizing biocides practical for use in ballast treatment plants.

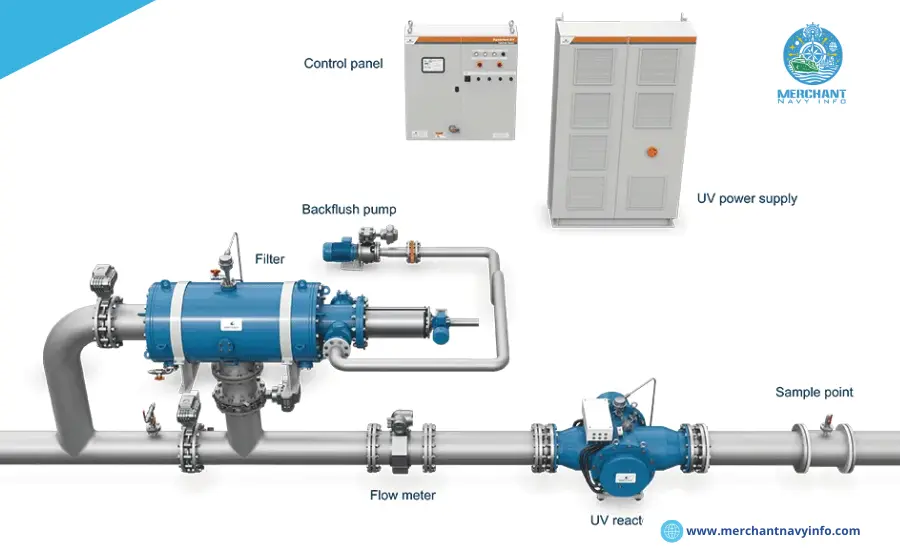

Ultraviolet Treatment Methods

Ultraviolet treatment methods for ballast water consist of UV lamps surrounding a chamber through which the ballast water flows. The UV lamps (amalgam lamps) produce ultraviolet light that acts on the DNA of organisms, rendering them harmless and also preventing them from multiplying. This method is used worldwide to filter water and is effective against a wide range of microorganisms.

Oxygen Depletion

As the name suggests, the oxygen removal method of ballast water treatment involves flushing/removing oxygen from to the ballast water tanks to suffocate the organisms. This is usually done by injecting nitrogen or also other inert gas into the space above the water level in the ballast tank. It usually takes about 2-4 days for the inert gas to suffocate the organisms. Therefore, this method is usually not suitable for vessels with short sea journeys. Additionally, such systems can also be used on vessels with fully enclosed ballast tanks. If the ship is already equipped with an inert gas system, the oxygen removal system does not require any additional space on board.

Thermal treatment:

In this treatment, the ballast water is heated to a temperature at which living organisms are killed. A separate heating system can be used to heat the ballast water in the tanks, or at the ballast water can be used to cool the ship’s engines, where the heat obtained from the engines disinfects microorganisms. However, such treatments can take a long time to inactivate the organisms, and they also promote corrosion in the tanks.

Cavitation or ultrasonic treatment:

Ultrasonic energy is an used to generate high-energy ultrasound waves, which kill the cells of living organisms in the ballast water. Such high-pressure ballast water cavitation technologies are also typically used in conjunction with other systems.

Electric Pulse/Plasma Treatment

Electric Pulse/Plasma for Ballast Water Treatment is still at the development stage. This system uses short bursts of energy to kill microorganisms in the ballast water. Pulsed Electric Field Technology uses two metal electrodes to create very high power density and also high-pressure energy pulses in the ballast water. This energy kills organisms in the water. In electric plasma technology, high energy pulses are sent to a mechanism placed in the ballast water, which creates an arc of plasma to kill living organisms. Both methods are said to be roughly equally effective against living organisms.

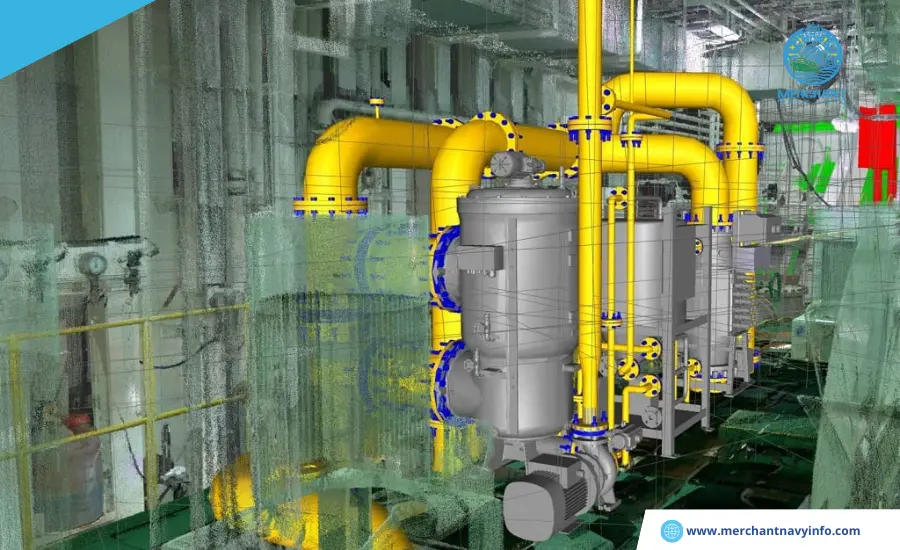

A typical ballast water treatment system on a ship Most ballast water treatment systems. Use two or three disinfection methods in different stages. A typical ballast water treatment plant consists of two stages. Where physical separation is used in the first stage and disinfection techniques in the second stage. The choice of a combined treatment system depends on various factors such as the type of ship, the available space on board and, also as already mentioned, cost constraints. A typical ballast water treatment system on a ship looks like this: also Every month, several new technologies for ships’ ballast water treatment are launched on the market.