Industrial Hygienist

Home / Health & Safety / Industrial Hygienist

Things You Should Know About Industrial Hygienist

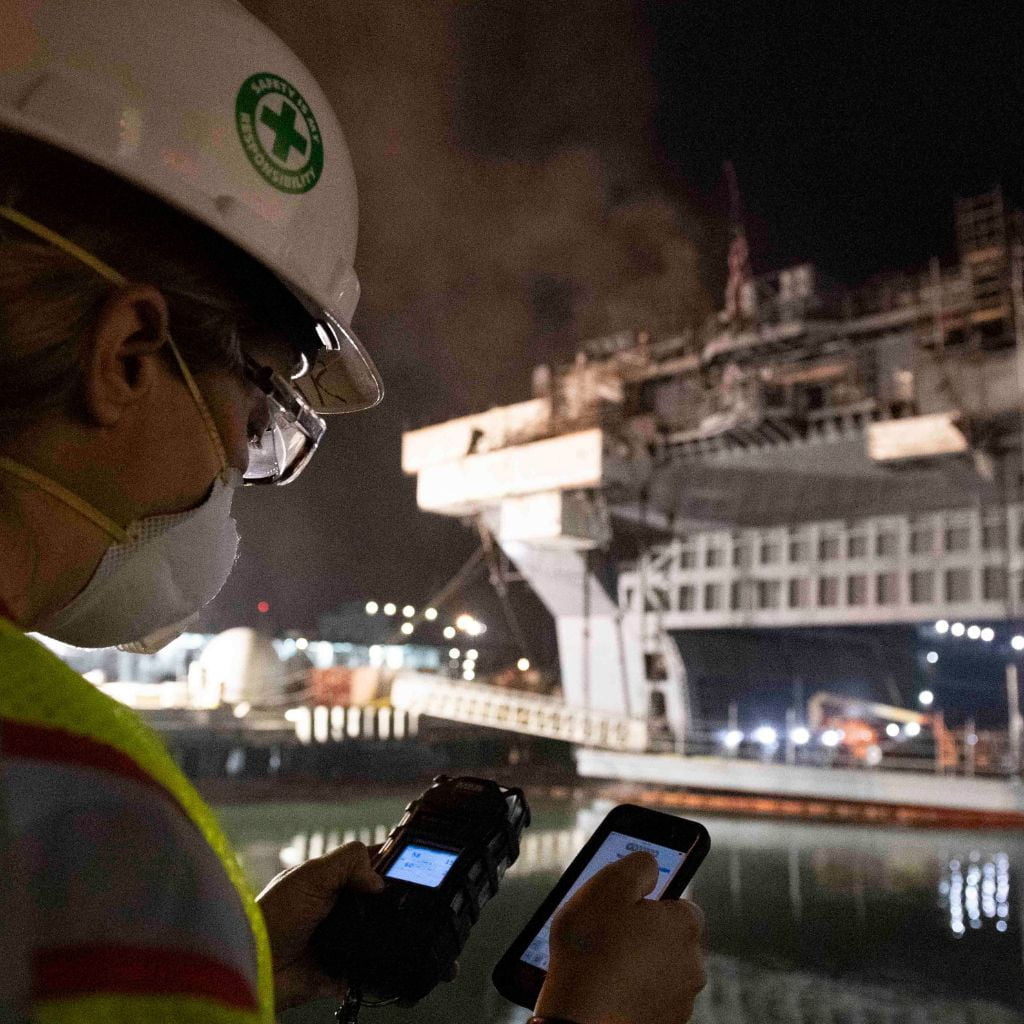

Industrial Hygienists (IHs) are the science-based guardians of worker health and safety. They act as detectives, identifying and evaluating environmental hazards in workplaces and strategists, implementing solutions to minimize or eliminate those risks. They have a diverse set of expertise in fields such as chemistry, biology, physics, and engineering. These skills blend well with safety principles to create safe and healthy work environments for everyone.

They are of growing importance in the modern-day workplace. These health professionals are at the forefront of the fight for worker rights and health care.

The Qualifications and Training of Industrial Hygienist in the Merchant Navy

To become an Industrial Hygienist, one needs to have a certain level of education:

- Bachelor’s degree: Typically in environmental science, public health, industrial hygiene, or a related field.

- Master’s degree: While not always required, it can enhance your career growth and specialize in specific areas. While earning a master’s degree in industrial hygiene is optional, it can provide students with in-depth education about industrial hygiene practices beyond their bachelor’s degree education. By earning a master’s degree in industrial hygiene, you can enhance your employability and the potential to achieve mid-level or senior-level industrial hygiene roles.

- Certification: Earning a certification can help an industrial hygienist improve their skills, adapt to industry updates and market themselves to employers. Consider researching entities that offer certification to experienced industrial hygienists with bachelor’s degrees and education specific to industrial hygiene. This may vary depending on your location and education level. Some examples of certifications include: The Certified Safety Professional (CSP) certification from the Board of Certified Safety Professionals (BCSP).

- Continuing education: Maintaining updated knowledge through ongoing training is crucial.

Job Description (key responsibilities)

Industrial hygienists assess safety conditions for industrial employees, including exposure to harmful chemicals, unsafe work procedures and other potential health hazards. Here are some specific examples of job duties for industrial hygienists:

- Travelling to construction sites, industrial plants and other facilities to perform inspections and collect samples

- Evaluating workplace procedures at industrial or manufacturing plants to determine the level of safety compliance

- Conducting tests on soil, water and air quality before the start of construction projects or in response to environmental safety concerns

- Working with managers or supervisors at industrial sites to introduce improved safety standards for employees

- Inspecting protective gear and safety equipment to determine whether it provides adequate protection from harmful chemicals or bodily injuries

- Creating educational materials and providing safety training to industrial employees, managers and supervisors

- Identifying risks to the wellbeing and safety of others and coming up with potential solutions to eliminate those risks

- Comparing their assessments of a work site to government laws or guidelines to determine whether a work site meets legal standards

- Inspecting ventilation mechanisms at work sites that handle dangerous chemicals to determine the level of exposure to employees and the surrounding community

- Interviewing employees to learn more about previous workplace injuries, health conditions and safety concerns

The Skills, Opportunities, Challenges of Industrial Hygienist

Industrial hygienists need various technical and soft skills to effectively complete their duties. Here are some examples of beneficial skills for these employees to show in their work:

- Attention to detail: Industrial hygienists can benefit from having excellent attention to detail because it allows them to notice small details when evaluating workplace procedures that could turn into health and safety hazards.

- Interpersonal communication: Interpersonal communication skills help industrial hygienists interact with individuals with limited knowledge of health and safety topics and testing methods. Their ability to speak about technical topics in a way that anyone can understand influences the success of training initiatives and changes to workplace practices.

- Ethical mindset: Industrial hygienists should have an ethical mindset that enables them to follow legal compliance laws or guidelines and report unsafe activities at work sites.

- Written communication: Written communication skills help industrial hygienists write reports on the state of a workplace’s health and safety steps and training materials for managers and employees to reference in the future.

- Soil testing: Industrial hygienists use professional testing equipment to drill down into the earth, retrieve soil samples and test them for hazards like radiation or lead.

- Air quality testing: Industrial hygienists use testing kits to take air samples in industrial environments. They can use the results of these tests to determine levels of pollutants like asbestos, mercury, glyphosate or lead.

- Water testing: Water testing includes testing the pH of a water source and whether there are hazards like lead or pesticides. Industrial hygienists conduct water tests of bodies of water near construction sites or industrial plants to ensure it’s safe for employees to work near them.

- Physical stressor assessing: Physical stressor assessing is a type of assessment that industrial hygienists conduct as they inspect workplaces for potential hazards. This includes looking at the effects of heat, confined space, noise level and other factors that could inflict stress on employees’ physical or mental health.

Challenges:

- Work can involve exposure to hazardous environments. This is a huge problem on the high seas, as getting supplies is an issue. The

- Keeping up with evolving regulations and technologies.

- Balancing cost-effectiveness with safety measures.

- Gaining buy-in for recommended changes from management and workers.

Opportunities:

- Rewarding career protecting worker health and safety.

- Diverse work environments in various industries.

- Growth potential with specialization and leadership roles.

- Competitive salary and benefits.

Frequently Asked Questions About Medical Officer

Strong analytical skills, problem-solving abilities, excellent communication, and the ability to work independently and as part of a team are essential.

Understanding scientific principles and methodologies is crucial for hazard assessment and control.

Some potential employers include manufacturing, construction, healthcare, mining, government agencies, and consulting firms.

The Bureau of Labor Statistics is looking at a 7% growth in IH employment by 2030, faster than the average for all occupations.

Contact professional organizations like the American Industrial Hygiene Association (AIHA) and explore educational programs in related fields.