Ships, whereas cruising, utilize seawater for a few purposes. The seawater is utilized within the ship’s framework and released after the utilization. Be that as it may, seawater contains a few marine life forms that enter the dispatch together with the seawater. And store and prosper on the parts of the ship’s framework. In the event that preventive measures are not taken. Marine development can cause damage to a specific portion in the long run. In this article, we are going learn about the causes and impacts of marine development in a ship’s framework. Together with the measures to battle it with MGPS.

What Causes Marine Development?

Ocean water contains both large-scale and miniaturized scales. Marine life forms such as ocean worms, mollusks, barnacles, green growth, difficult shells like oak seed barnades, etc. These organisms stick to the surface of the transport and thrive over there, coming about in marine development.

Marine fouling can frame tremendous clusters of marine development inside the transport channelling framework. This can be basically caused by the entry of seawater into the seawater framework. The life forms discover the idealized spot interior, the framework wherein the natural conditions and other significant components, such as temperature, pH, supplements, etc., are suitable for them to breed and spread.

Impacts of Marine Development

As the marine life forms flourish, they piece and contract the entry of cooling water. Within the ship’s framework, coming about within the taking after variables:

- Disabling the warm exchange framework.

- Overheating of a few water-cooled machineries.

- Increment within the rate of erosion and diminishing of pipes.

- Diminished productivity can lead to the misfortune of vessel speed and misfortune of time.

Battling Marine Development

To maintain a strategic distance from arrangement of marine development MGPS or marine development preventive framework is utilized onboard transport. The portrayal and working of MGPS are as follows.

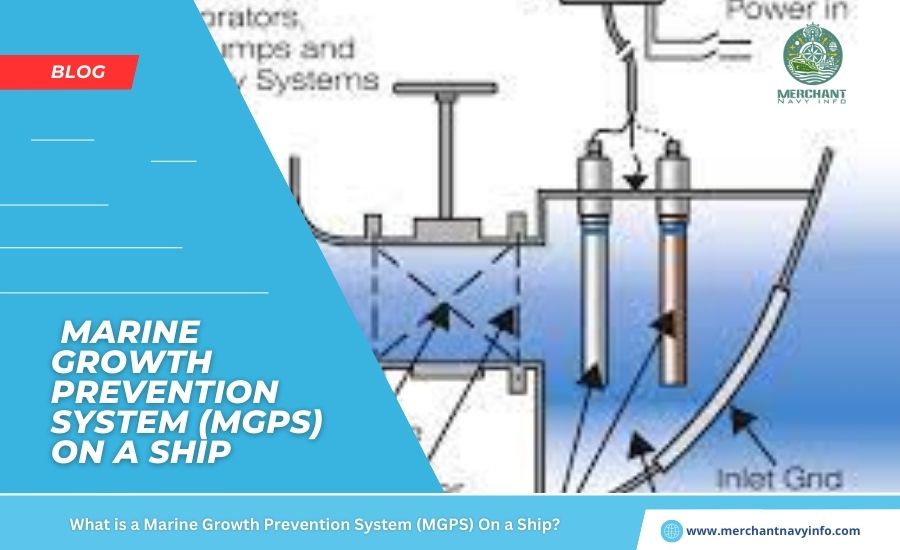

Fundamental rule on which MGPS runs is electrolysis. The method involves the utilization of copper, aluminum and ferrous anodes. The anodes are normally fixed in sets within the primary ocean chest or in such. Put where they are within the course of the stream of water.

The Framework Comprises

It is of a control unit that supplies awed current to anodes and screens them. While in operation, the copper anode produces particles, which are carried absent by water into the channeling and apparatus framework. The concentration of copper within the arrangement is less at that point, 2 parts per billion, but sufficient to prevent marine life from settling.

Due to the inspired current, the aluminum/ferrous anode produces particles. Which spread over the system and creates a hostile to destructive film over the channels. Warm exchanger, valves, refrigeration, ac unit, etc, internally.

Here Are 17 Tips To Guarantee Marine Growth Prevention (MGPS) Continuously Give Top-Notch Execution To Induce The Benefits Expressed Above:

- Guarantee there are no aluminum channels or parts joined to the seawater framework in which MGPS copper anodes are associated. In a copper-based anode or MGPS framework, the aluminum will have a chemical response and act as an anode within the region of copper, driving serious erosion of aluminum parts

- The current settings for the MGPS should be continuously updated as endorsed by the creator. A tall current esteem setting will lead to an shorter anode life, and a lower current setting will increment the anode life

- The typical current esteem on which the lion’s share of MGPS anodes work comes within the run of 2 amps per anode. This esteem can be physically balanced in a run of 0.2 amp steps

- When the MGPS is introduced on a non-ferrous metal surface (e.g. pipe upstand), the establishment spines of the anodes must be given with a confinement fabric to guarantee there’s no electrical contact between the anode and the non-ferrous surface, i.e. between two divergent metals

- When the MGPS anode get together is introduced on the strainer (the anodes more often than not are introduced on the strainer top), it is basic to accurately put the anode interior on the strainer bushel in such a way that the anode surface is does not touch any metallic components

Corresponding Tips

- At whatever point the strainer is opened up for assessment or cleaning by lifting the cover, guarantee to disconnect the supply of these anodes and not to harm them when evacuating the strainer wicker container lifting bar

- When the MGPS anodes are introduced in an ocean chest, guarantee they are not set within the “dead zones,” i.e. where the water stream is negligible. They should be mounted within the central section of the seawater flow from the channel frameworks to the seawater suction

- Guarantee not to utilize oversize cables for the MGPS anodes, as they are much likely to cause mechanical over-burden on the terminal pieces.

- Beneath day-by-day watchkeeping obligations, check that the computerized show ammeters are working appropriately. When an anode has nearly been consumed, the comparison will show a moo esteem.

- In the event that the anode current esteem is dropped to a moo level, turn off the current handle to zero. i.e., there is no supply to the anode, so reestablish the anode at the first chance. After recharging the anode, reset the current to the previously given current settings

- For treatment tank sort MGPS, open the discuss vent on a daily premise to avoid discussing pockets inside the tank

- When supplanting or reestablishing the anodes, guarantee to carefully unscrew the mounting nuts to anticipate the anodes falling down the ocean chest, which may harm the chest or the anode itself

Taking After Focuses To Be Considered When Working On MGPS Framework In Drydock:

- While opening the anode, never lift or bolster the anode from its cable or apply any mechanical stack to the anode cable.

- The unused save anode, which is of a held-in sort or spine sleeves sort, is provided unpainted with a rust anticipation coating. Guarantee to expel this coating sometime recently the establishment. Never utilize a wire brush or mechanical instrument to expel this layer. White spirits or turpentine can be utilized to expel this coating.

- In the event that anodes are introduced in a space where blast cleaning or portray isn’t wrapped up, they must be reasonably secured. Sometime recently, the spaces were flooded; check to guarantee that the assurance has been evacuated. Moreover, evacuate any paint, tape cement buildup or oil from the anode surfaces.

- Guarantee the reestablished anodes are mounted within the vertical position unless something else expressed by the creators or producer.

- Amid dry docking for retrofit frameworks, sometime recently, the vessel has been propelled or refloated. Check the separation of each anode from the frame, as well as the continuity of the positive bolster circuit to the anode

Conclusion

The MGPS introduced on a transport must be effective against an expansive assortment of living beings due to the numerous numbers and complex nature of fouling communities in waters of diverse parts of the world the dispatch handles.

Any antifouling operator utilized inside the MGPS must comply with the neighborhood and worldwide directions and necessities. Especially almost biocidal releases. MGPS anodes are fitted with uncommonly outlined security caps, which makes a difference in evacuating the anode for substitution onboard dispatch. Regularly, MGPS has a planned life that coincides with the dry dock of the vessels.