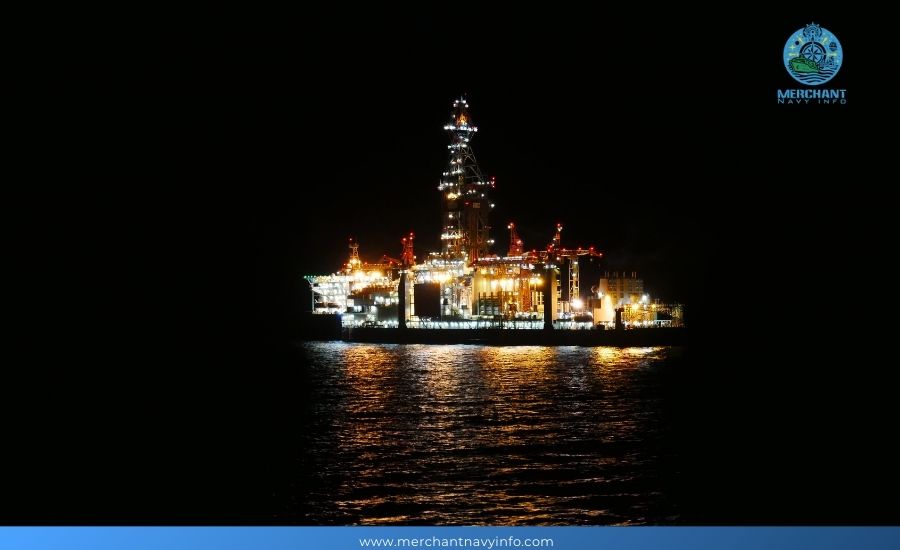

Everything You Need to Know About Offshore Vessels

Offshore vessels are vessels used for exploration, drilling, and oil and gas production in marine environments. This seems fairly straightforward, but wait a minute because offshore vessels encompass various vessels that all play a role in the offshore shipbuilding industry.

Cargo and container ships can also be divided into different types of vessels…

- Bulk carriers

- Feeder vessels

- Oil tankers (including chemical tankers, oil tankers, and gas tankers)

- RoRo vessels

- Car transport vessels

- Reefer vessels

- Feeder vessels

- Coastal transport vessels

Offshore vessels can also be used in this capacity. We’ll look at these types in more detail throughout this article. So let’s get started!

What are some of the different types of offshore vessels?

You may also see offshore vessels abbreviated to OSVs: these can stand for offshore supply vessels or support vessels. And the acronyms don’t stop there, as you’ll soon discover!

Looking for offshore vessel jobs? Check out offshore vessel jobs now!

In short, offshore vessels can be divided into four main types:

1. Oil exploration and drilling vessels

These vessels are used to search for and drill for oil and gas at sea, and this category of offshore vessels includes:

Drilling vessel

Drilling vessels are large, self-propelled vessels that drill for oil and gas in deep water. They are equipped with drilling equipment and a drilling rig – a tall, grid-shaped tower used to drill a hole for an oil well before pushing the drill pipe deep into the seabed.

Semi-submersible vessel

As the name suggests, a semi-submersible vessel is partially submerged in water. They are floating structures with a large deck and multiple legs connected underwater at their base by floating buoys. Their role is to drill for gas and oil in deep water.

Jacking platform

Unlike semi-submersible and drilling vessels, jack-up platforms drill for oil and gas in shallow water. Also known as self-elevating units, they are mobile platforms that raise their self-floating hull above sea level. Their movable legs mean they can be moved anywhere they are needed.

Offshore Barge

Like any barge, an offshore barge or oil barge is a wide, flat-bottomed, non-self-propelled boat that carries cargo—in this case, oil. However, unlike an oil tanker, which is used to transport huge amounts of oil over long distances, offshore barges are smaller and designed for short-distance transport.

2. Offshore Production Vessels

These vessels assist in drilling production operations, and this class of offshore vessels includes:

Floating Production Storage and Offloading Vessels

Commonly referred to as FPSO vessels, these are large floating platforms used to produce, store, and offload oil and gas. Most FPSO vessels are moored in one location for an extended period.

Single Point Mooring Tank Platform

Also known as a SPAR platform, this floating oil platform offers a more stable alternative to traditional platforms and is typically used in deep waters. Its design comprises one or more large vertical floating cylinders supporting the deck. SPARs are permanently anchored to the seabed by rigid cable lines.

Shuttle Tanker

Some oil platforms or offshore vessels use a series of pipelines to deliver oil to a refinery onshore (see Pipelay Vessel below) while others may use a shuttle tanker. This vessel is equipped with unloading equipment compatible with the oil field, platform, or vessel it works with.

Tight Leg Platform

A tight-leg or extended tight-leg platform is a floating structure vertically attached to the seabed by steel ropes connected to driven piles. It is used for oil and gas exploration and production.

3. Offshore Support Vessels

These vessels support oil exploration and drilling vessels, and OSVs include:

Platform Supply Vessel

As you may have guessed, Platform Supply Vessels, or PSVs, transport supplies and other equipment to offshore oil and gas vessels and platforms.

These can include drilling equipment, materials, and fluids such as drilling water, bentonite, cement, barite, liquid mud, oil, chemicals, and methanol.

Logistics support vessels can also be used to provide support in the event of a need for medical assistance or firefighting services.

Anchor Handling Tug Supply Vessel

An anchor-handling supply vessel, often abbreviated as AHTS, is a tugboat used to tow and anchor ships in the open sea. It will also provide emergency assistance if requested.

Accommodation Vessels

Some offshore workers sleep on their boats or platforms, while others head to nearby anchored vessels at the end of the workday or shift. These vessels are called accommodation vessels, or ACVs. They typically have rooms, cabins, dining rooms, and recreational facilities such as gyms.

Seismic Research Vessels

Seismic research vessels map geological features on the seafloor to determine the best locations for offshore oil or gas exploration. They do this by firing air cannons that transmit sound waves to the seafloor. A hydrophone (a microphone specifically designed for underwater use) towed behind the vessel picks up the echoes of the shots.

4. Offshore Construction Vessels

These vessels help build various structures offshore, and these vessels include:

Diving Support Vessels

DSVs (Diving Support Vessels) are equipped with specialized equipment for underwater operations, including diving, inspection, repair, and maintenance.

Crane Vessels

Crane vessels’ primary purpose is to assist in the construction of offshore structures typically associated with the oil and gas industry. They are classified into three types: regular, semi-submersible, and ram crane vessels. These vessels can also assist in rescue operations.

Heavy Lift Vessels

Heavy Lift Vessels (HLVs) are designed to transport cargo far larger in size and weight than the items commonly found on container ships. Examples include dredging equipment, docks, floating dry docks, drilling platforms, offshore structures, and other vessels.

Pipelay Vessels

Pipelay vessels, also known as pipelay vessels or simply PLVs, are vessels used for underwater infrastructure construction. They connect oil production platforms to onshore refineries.

Why does the oil and gas industry require so many different vessels?

The oil and gas industry relies heavily on the functions that its offshore vessels must perform. Some ships allow companies to explore and drill for oil and gas, some can produce raw materials, some provide construction services for the platforms and equipment, and some provide backup and support services.

Of course, other ships shuttle crews to and from their ships, platforms, or offshore platforms at the beginning and end of their contracts.

What are the characteristics of ocean liners?

Because offshore vessels associated with the oil and gas industry often need to operate in dangerous locations and conditions and handle and process hazardous materials, they are subject to strict safety regulations. Their crews must have rigorous training and skills.

Due to the nature of their work, most naval vessels are large and have complex onboard infrastructure and equipment. Naval vessels are among the most technologically advanced ships in the merchant fleet.

In recent decades, the demand for offshore vessels of all types has increased dramatically due to the expansion of the oil and gas industry, and for companies to reach their full potential, these ships, rigs, and platforms must increasingly feature the latest technology and technology. Technology. Technology.

Is it dangerous to work on a ship or offshore platform?

We won’t sugarcoat it and tell you that working on an oil rig or ship is a piece of cake.

Crews on any vessel and workers on oil rigs and drilling platforms face certain risks. More serious are injuries caused by the equipment or machinery they handle, damage caused by cargo (i.e., oil or gas), or even being washed overboard during bad weather.

However, if you talk to countless people who have worked abroad, they will likely tell you that the benefits of working abroad are enticing, even if they are away from home for months.