Windlass on ship play a vital role in steering ships and berthing them safely in ports and on the high seas. To hold the entire ship (weighing hundreds of tons) in place, a heavy load. The so-called anchor head, provides the necessary resistance. Have you ever wondered how such a heavy load is lowered from the seabed and pulled up again?

A mechanical device called a winch is used for exactly this purpose. A winch is a pulley or mechanical system used to move large weights vertically or horizontally. It was invented by an ancient Greek scientist is an Archimedes. And was used for general purposes such as drawing water from wells and lifting heavy construction machinery.

As technological advances increased the demands on the shipping and cargo transport industries. Heavier windlass on ship, required for stopping larger ships, also came into use. For this reason, more advanced hoisting systems were also used to operate the windlass on ship and associated machinery effectively. In this article, we look at what a windlass is and how it works.

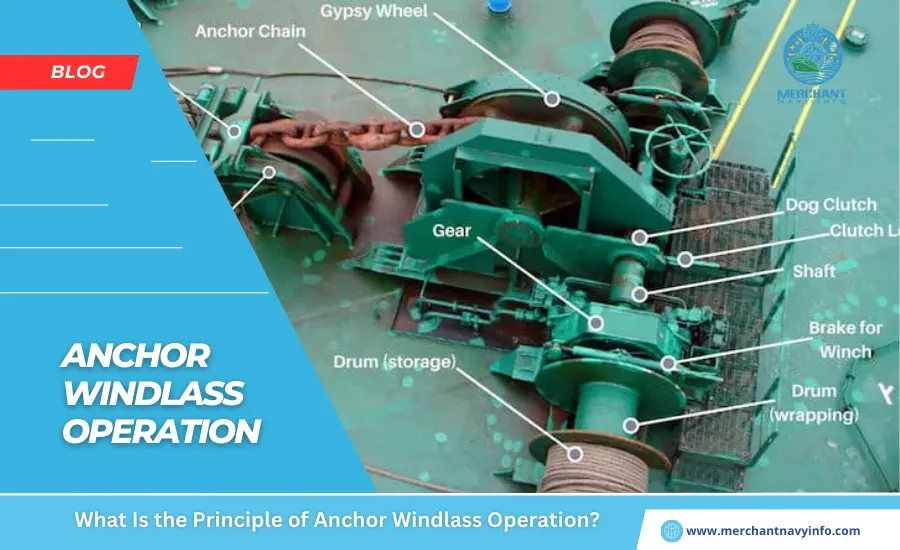

Basic Structure of an Anchor Windlass on a Ship

An anchor winch is a device that moves fairly heavy weights using a pulley system. The barrel with the chain or cable wrapped around it is driven using a belt or crankshaft. This wave creates a circular motion that allows heavy loads. To be lifted without the energy normally required to pull a heavy load. The crank can be operated by hand (such as pumping water from a well) or by a motor (such as a large construction crane). And is attached to the barrel so that it can rotate around a central axis.

The principle of using a pulley design is that large weights. Can be lifted by distributing the load over multiple cables rather than a single chain. This means that with a limited amount of force, very heavy loads can be lifted effectively. The problem with using such designs is that they place heavy loads on the cables and chains used to move the load. If the mechanism stops in the middle of an operation, appropriate measures must be taken to prevent the cable from breaking due to tension.

Most materials can suffer fatigue or stress failure when subjected to tensile loads. Therefore, for anchor winches that have to lift almost a tonne, special mechanisms must be used to ensure that the weight of the anchor head is removed from the anchor chain during stoppages. This is explained in more detail in the next section.

Where is the Windlass?

On ships and large vessels such as container ships and oil tankers, the windlass is located in a special place at the bow of the ship, called the windlass room or windlass room. However, on some ships the anchor winch is also installed on the foredeck. The advantage of having the windlass on ship is that it allows a greater degree of control when operating the equipment. In addition, the space that would have been occupied by the windlass room can now be put to good use as a popular storage location on board the ship.

Having a windlass on ship also improves emergency access. It is easier for the crew to operate the windlass if it is located on the upper deck rather than in an enclosed space, especially if a manual or semi-manual system is used. However, if the windlass is located on the top deck, it is also at risk of damage from the elements. Generally, the foredeck is subject to green water loads (rare but possible) and bow shock.

Green water pollution refers to water that accumulates on the deck of a vessel due to high waves. The foredeck is designed to prevent this, but natural elements such as waves are unpredictable, and windlass equipment can still get wet. Another problem is bow shock. During a storm, the bow may briefly rise out of the water and then be struck by a ship’s bow.

Impact

This violent impact can have a detrimental effect on an open winch system. Finally, a problem with locating the capstan on the upper deck is that it creates a safety hazard that can impede personnel movement.

Small vessels do not have windlasses due to the light weight of the anchor head. Medium-sized vessels often have a single windlass to control the port and starboard windlass on ship. It is a simple mechanism in which a single winch controls the anchor ropes on both sides. However, larger vessels where a higher level of precision is required are fitted with separate windlass systems for both windlass on ship. Such a design is called a split windlass and is effective in performing close manoeuvres when the ship is in port or at sea.

How An Anchor Winch Works

The key point in the naming of the word “anchor winch” is that it generally refers only to the horizontal movement of weight. A “spill” is a device for vertical movement. For effective use, a windlass is often combined with a capstan to give the master or the person operating the winch a greater degree of control.

This device is used to release, hold and manipulate the anchor chain, which is made of metal links. These links fit into notches or grooves in the central windlass drum, which gradually release the links.

The windlass can be controlled remotely are from the bridge but can also be cranked manually using a lever and brake system located next to the windlass. There are two possible handling methods for releasing or lowering an anchor into the water: either by lowering the anchor or by letting the head fall freely.

Each of these methods has its own advantages, but the motorized version is often used on ships and large boats. In the motorized version, the windlass rotates slowly in the direction that the anchor chain is released. When the mark on the anchor chain indicates that the required length has been reached, the crank operator can apply the brake on the winding drum.

Advantage

The advantage of this method is that the heavy anchor head falling does not exert a sudden large force on the hull because the large weight descends gradually. This allows for greater control. It is also possible to move the anchor head to the desired position by operating the anchor winch control. The free fall option is more commonly used on small and medium sized boats.

This is because the freeboard is relatively low, and the water surface can reduce the force of the falling weight. However, slight flooding of the deck and significant vibrations can still occur, which can affect the stability of the vessel. The advantage of the free fall option is that it is significantly faster than slowly cranking the winch. However, you have little control over where and how the anchor hits the water. The various components that make up a winch basically include the winch, dog clutch, sprocket drum, pawl, and hose.

The Winch Works in the Following Steps:

- The electric motor rotates the winch, which in turn rotates the winch drum.

- The dog clutch is first engaged with the winch.

- The clutch starts cranking the sprocket in a particular direction and at a particular speed.

- The chain guide is used to hold and control the anchor chain throughout the process.

- The chain is threaded down the hose line until the desired anchor length is reached.

- A ratchet or devil’s claw is used to hold the anchor rope in place.

- To release the claw, put the sprocket into reverse gear to release tension on the rope.

- The chain can be lifted by simply reversing the direction of the winch drum.

- Safety Precautions and Conditions

Maintaining safety is essential when working with heavy machinery such as winches. To achieve a safety factor in a winch operation, the winch must be able to fully raise or lower the anchor head is at any speed within the prescribed operating speed range.